Textile insulation

Temperature reduction from over 1000 °C down to 60 °C.

- Short development times

- High security of supply

Our insulation solutions prevent fires

Optimum contact and fire protection with tmax Textile insulation

- Properties of textile insulation

- SOLAS, fire protection, contact protection and much more

- Short development times, high security of supply

- High-quality materials - a perfect fit for every application

- In 6 steps to the latest SOLAS-compliant fire protection

Get the probably most comprehensive e-book on the subject of textile insulation.

The best alternative to the metal insulation solution

The features of a textile insulation

SOLAS

Optimal contact protection

Fire protection

Soundproofing

Our textile insulation solutions are removable multi-component insulation shells, made of technical fabrics with incorporated insulation material. The insulation thicknesses depend on the structural requirements and the required insulation capacity.

This results in special advantages compared to other insulation solutions:

- Individual and custom-fit fabrication

- Individual production and series production

- Easy assembly and disassembly

- Suitable for applications in the high-temperature range

- Reduction of energy consumption and heat losses

- Minimization of heating times

From simple to complex. Small to large quantities

Meeting every customer requirement, from fast to extensive

Simply

- Measurement on site

- Make template

- Digitization

- Customization/Prototypes

- Production

Optional:

- Prototyping on site

Complex

- Measurement on site

- Make template

- Digitization

- 2D construction

- Programming

- Customization/Prototypes

- Production with partially

- automated production via cutter machines

- Base sampling

Complex +

- 3D data from customer

- Programming

- 3D printing

- 3D construction

- Customization/Prototypes

- Partially automated production via cutter machines

- Premium sampling

Optional:

- On-site measurement through mobile 3D scan

- Reverse engineering

The proof: contact protection of the highest quality

Optimum safety due to the highest material and quality standards

With over 45 years of experience as a solution provider in high-temperature insulation, tmax has been able to build a sophisticated research laboratory. In this laboratory, we can prove that our products deliver what they promise by using the latest technologies and broad technical know-how.

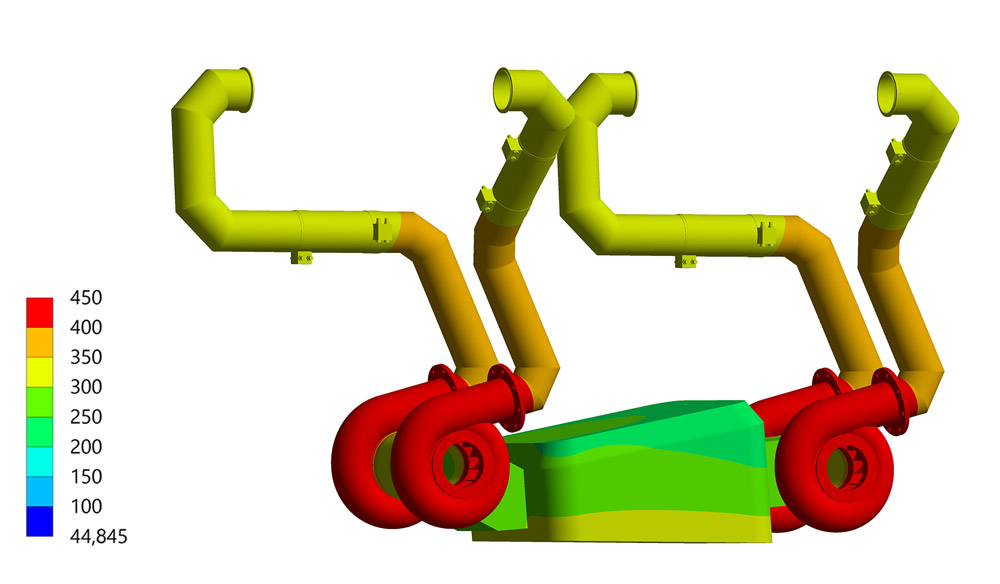

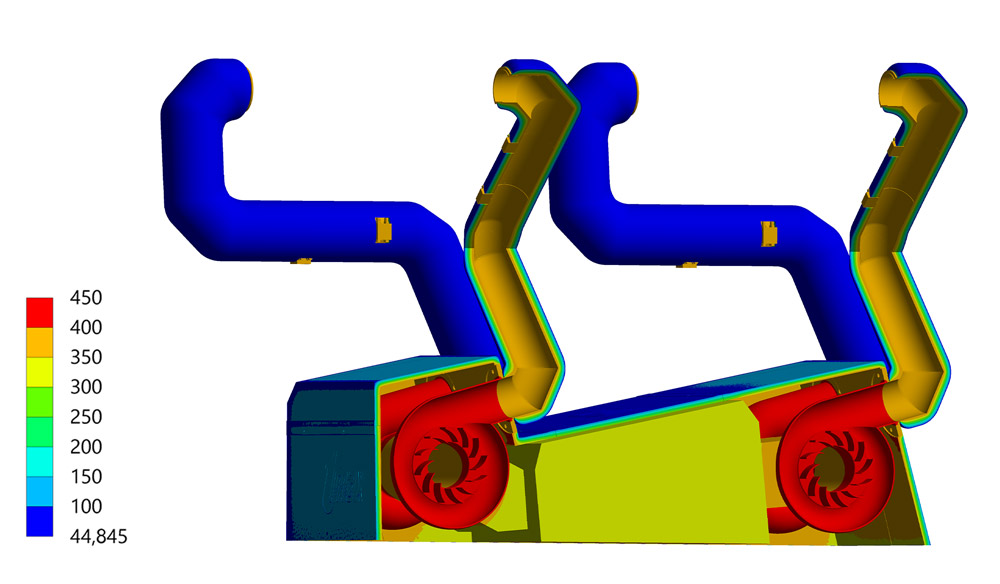

Our temperature simulation is used to determine temperatures at the surfaces of the insulation cladding, to be able to estimate whether the selected insulation configuration meets the required customer and legal specifications.

Exhaust gas values that were hardly imaginable in the past

Targeted temperature control in exhaust gas aftertreatment is the key to compliance with the increasingly stringent emission standards set by the legislator for internal combustion engines.

Temperatures are controlled in the entire exhaust tract in such a way that the optimum conditions for exhaust gas purification prevail at all times at key points, while at the same time protecting temperature-sensitive components from heat input.

To meet emission standards, tmax develops and produces numerous custom-fit solutions for all series sizes. Particularly through the use of tmax Textile Insulation, values are achieved today that were hardly imaginable in the past.

- Reduced fuel consumption

- Improved light-off behavior

- Reduced emissions of carbon dioxide, soot particles and nitrogen oxides

- Protection of surrounding components

Faster. More reliable. Textile insulation.

Short development times, high security of supply

Due to shorter development stages and the reduced use of tools, you have interesting advantages with a textile insulation solution compared to metallic insulation.

- Short development times

- Lower costs

Security of supply cannot always be taken for granted. Since all your projects are saved in shape, dimensions and materials, you can reorder from us at any time. Even after many years.

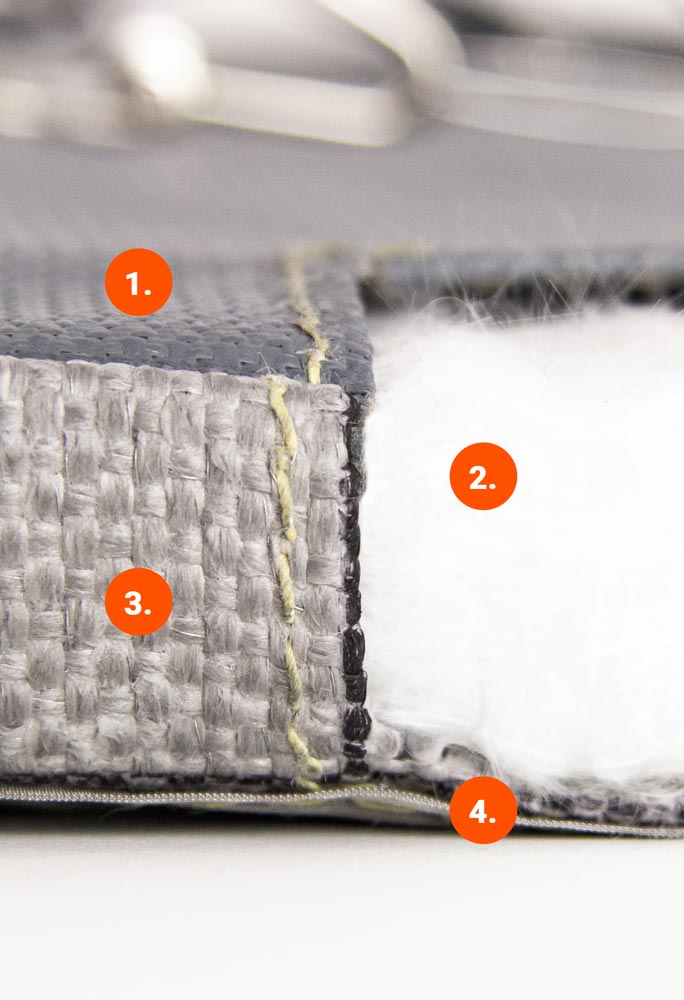

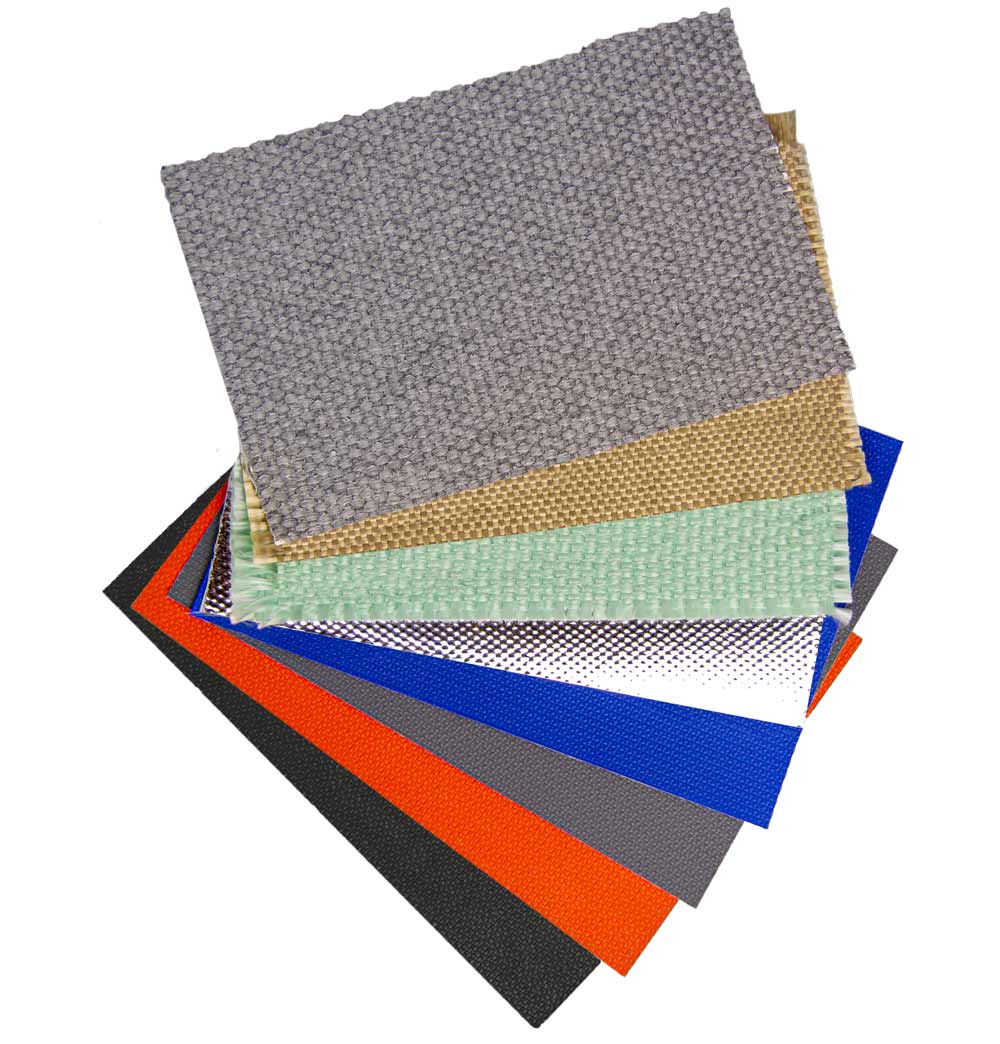

Structure of textile insulation

Meeting every customer requirement, from fast to extensive

The design and material combination of a textile insulation is always carried out according to the technical requirements as well as the individual customer wishes.

1. Outer fabric

- Low temperature load

- High resistance to dirt, water, oil, etc.

- High demands on appearance and haptics

2. Insulation material

- Glass fiber or silicate fiber mat

- Insulation effect controlled by different material thicknesses

3. Inner fabric

- Direct contact with hot component

- Temperature resistance up to 1000° C

4. Vibration resistant fabric

- Protects the insulation system from wear

- Increasing the service life of the insulation for dynamically loaded components

Highest quality materials, precisely fit for every application

Our custom-fit textile solutions protect people, machines and surrounding components from heat

Years of experience using high-quality materials in a wide variety of combinations and requirements allow us to customize textile insulation to fit any challenge and even highly complex shapes. In this way, the performance characteristics in relation to the

- Temperature resistance,

- Vibration resistance,

- Weather resistance,

- mechanical strength and

- Chemical resistance

can be controlled in a targeted manner.

Uncompromisingly safe:

tmax RETROFIT also with Textile

Precisely fitting insulation solutions, for older motors as well

Worn out insulation increases the risk of fire and thus hazards to people, machinery, and image. There is a risk of long downtimes and increased insurance premiums. To remain economical, outdated insulation must be replaced.

With tmax RETROFIT, this process can be made smooth.

With the all-in-one package, we offer you all services – from the creation of the 3D data of your engine to the thermography of the insulation system, developed and installed for you – from a single source.

Let’s talk, we have the answers.

- Efficient fire protection for man and machine

- Temperature reduction to below 220 °C - down to 60 °C on request

- Protection of temperature-sensitive components from heat radiation

- Minimum additional weight

- Safety from machine failure

- Cheaper insurance premiums