RETROFIT

100% SOLAS: Maximum protection from the market leader

More and more often, our solutions are as individual as your challenges. We combine the advantages of metallic and textile insulation materials and develop an insulation solution tailored specifically to your requirements.

Would you like to learn more? Arrange a no-obligation appointment with one of our experts for SOLAS-compliant RETROFIT solutions.

Less heat

More security

100 % SOLAS-compliant insulation solutions for older engines as well

Temperature reduction from over 1000 °C to SOLAS-compliant 220 °C – if requested, even down to 60 °C!

SOLAS

Fulfillment of exhaust emission standard

Fire protection

Fire protection without compromise

Safety must not be a question of the year of manufacture

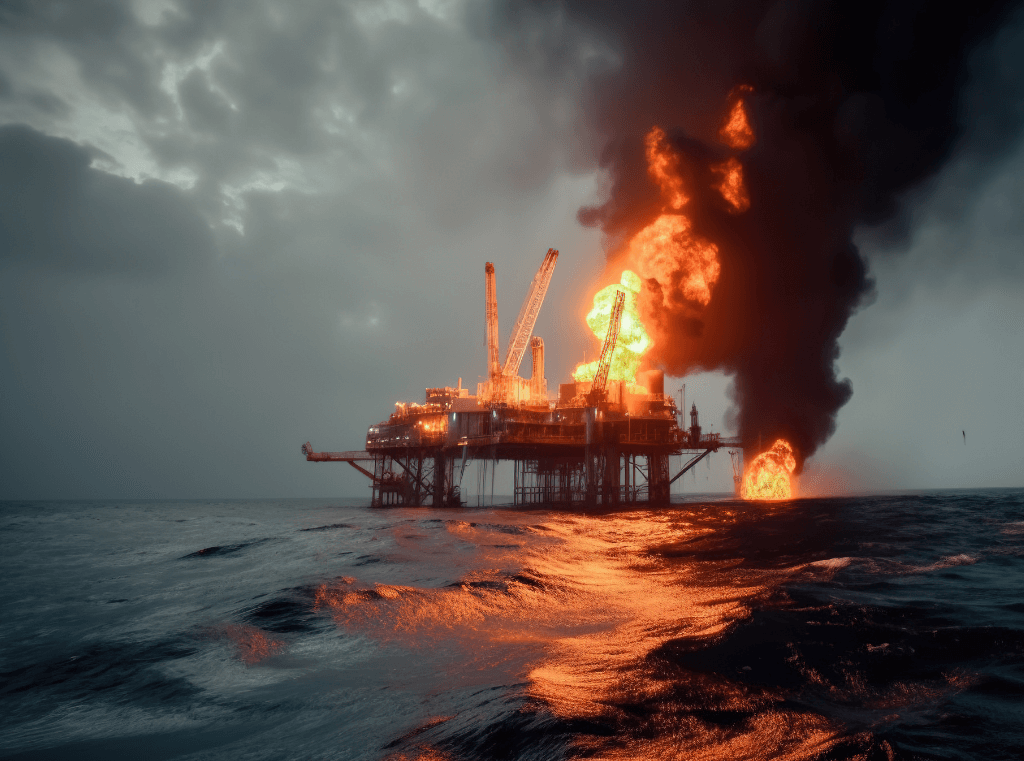

The rules apply to older ships and platforms just as they do to newer models: safety for people and machinery is the top priority, and compliance with legal safety requirements applies regardless of the year of construction. It is in the engine room, where the highest temperatures prevail near the engine, that the thermal risk is greatest and efficient fire protection is most important.

However, since 3D data is usually not available for older engines, retrofitting with SOLAS-compliant and high-performance insulation systems was only possible to a limited extent – until now.

The solution

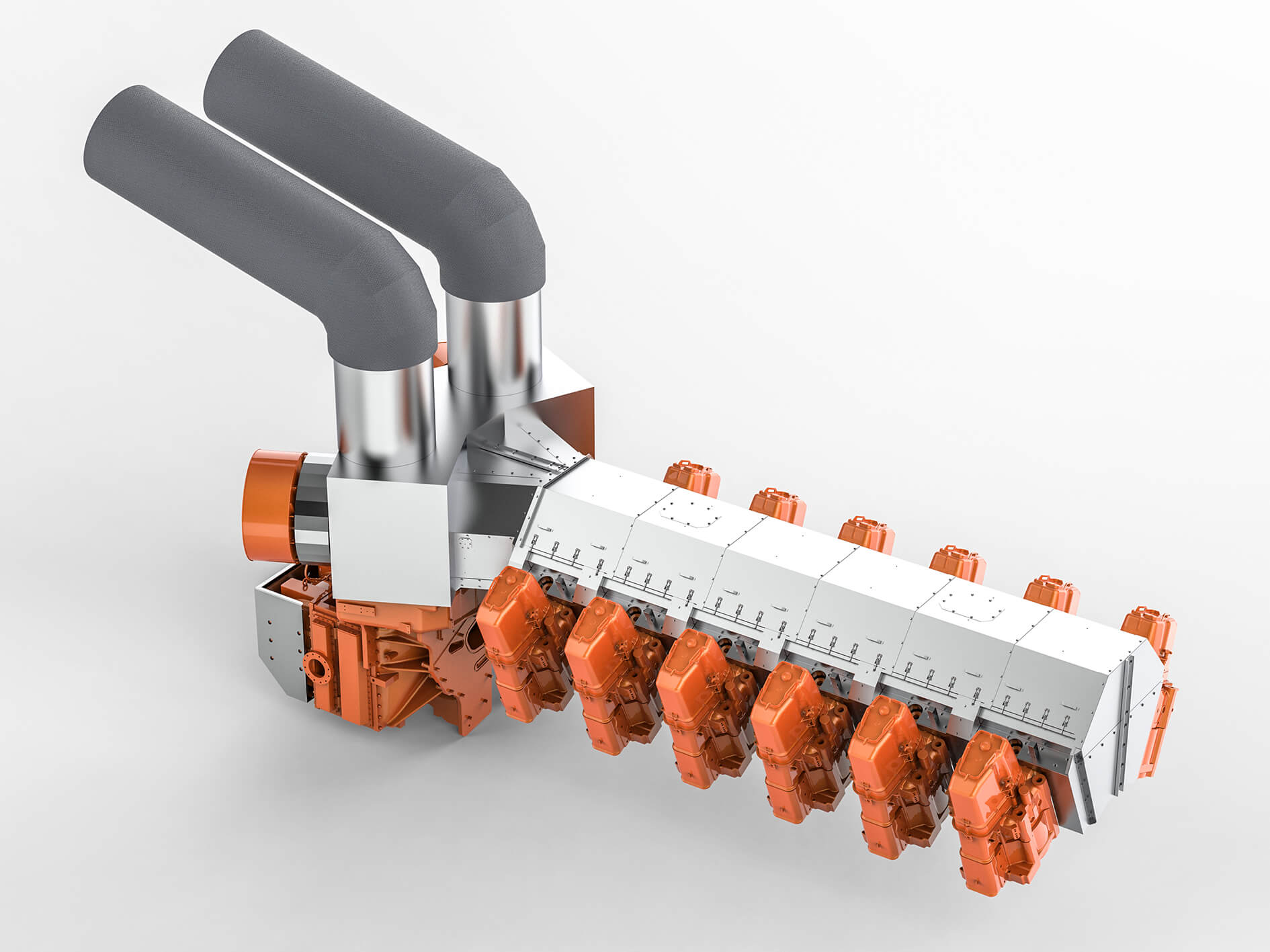

With tmax RETROFIT, older engines can now be retrofitted with high-temperature insulation systems that not only meet, but even exceed SOLAS guidelines.

The all-in-one package tmax RETROFIT offers all services, from the assessment of requirements to the installation of the newly developed insulation system, from a single source. Including the creation of 3D data on your engines and collaboration with the engine manufacturer.

Contents in this e-book

100% SOLAS: Maximum protection from the market leader.

- In 3 steps to modern fire protection

- Requirements for high temperature insulation

- Functionality of SOLAS compliant insulation

- The tmax SOLAS insulation concept

- Around tmax: competencies and services

6 steps to the latest fire protection

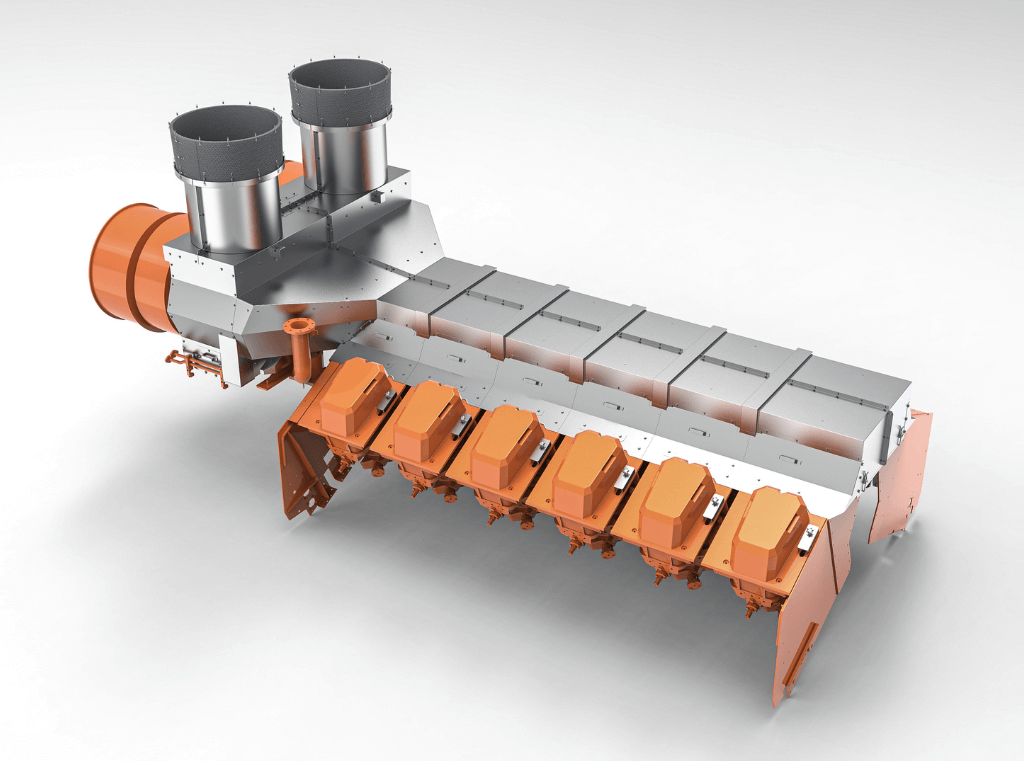

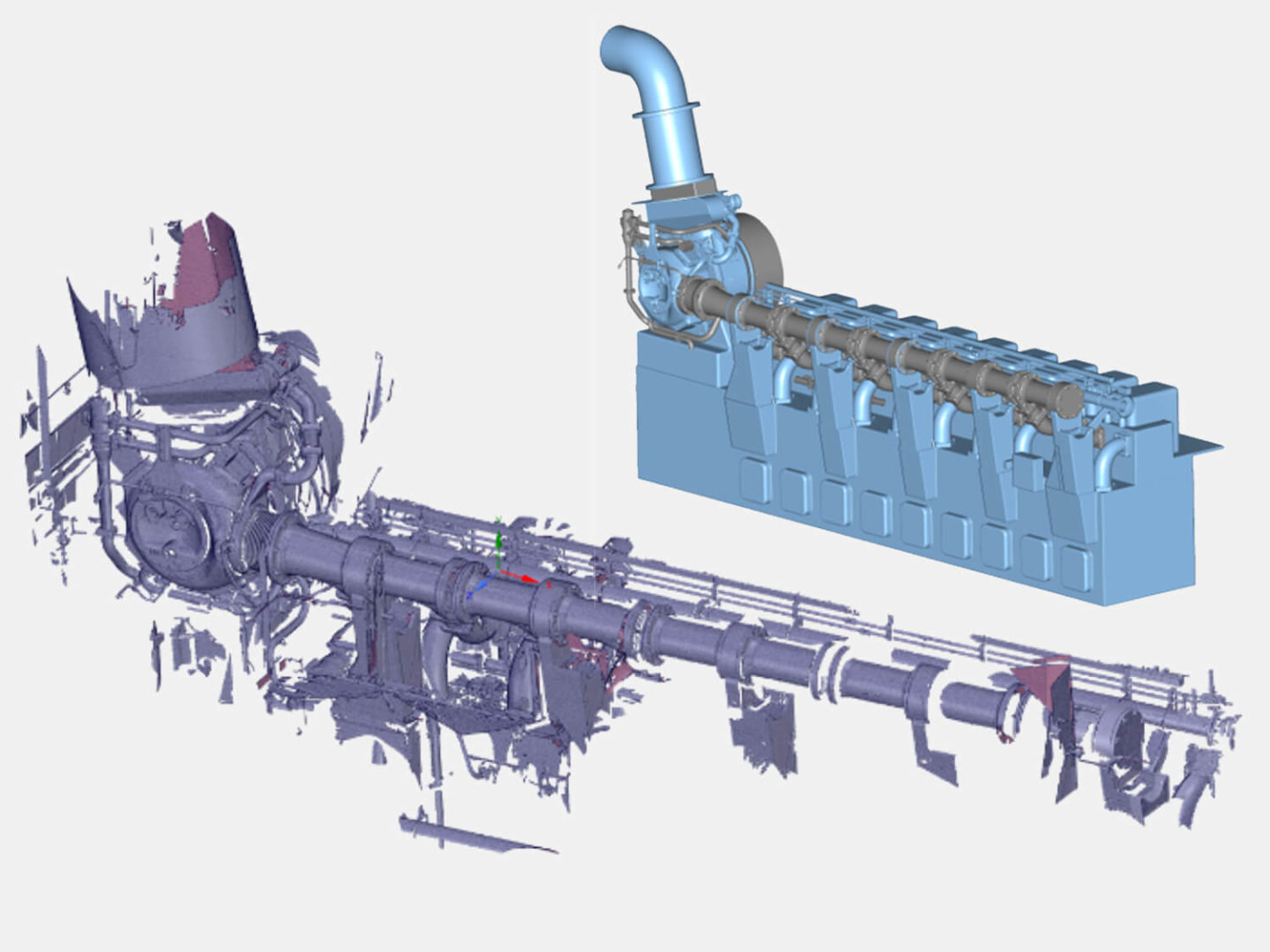

1. Mobile 3D scan

A suitable exhaust/turbocharger cladding can only be designed if 3D data from the engine is available.

No 3D data? – No problem:

With our high-resolution 3D scanner system, the data of your engine is converted into a parametric CAD model. This creates the basis for upgrading your engine.

2. Reverse engineering

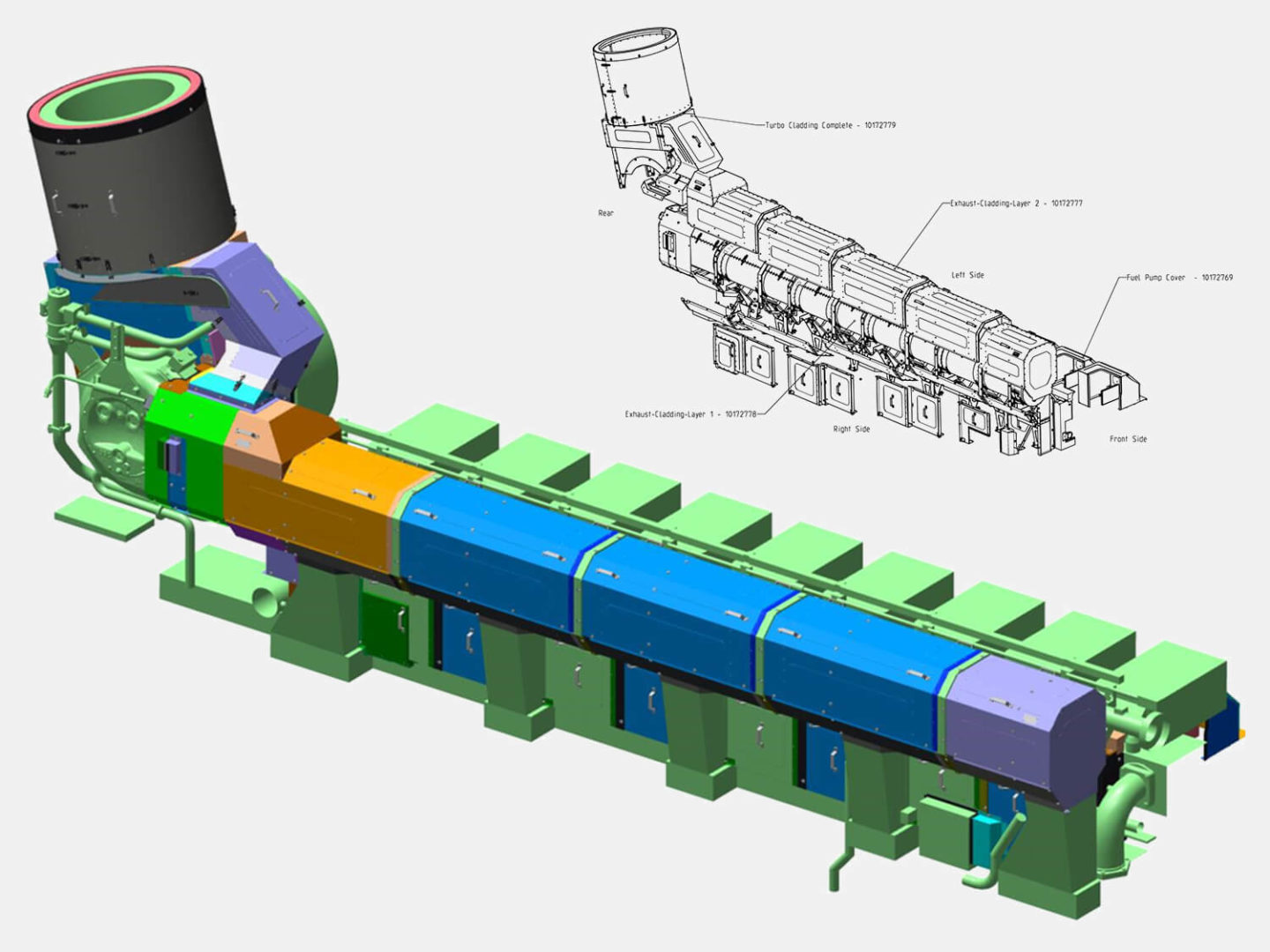

Based on the model at hand, our experienced designers develop a durable exhaust/turbocharger cladding that reliably reduces the maximum surface temperature to below 220 °C.

By using simulation methods, we can calculate the vibration behavior of the system and ensure SOLAS compliance as well as high durability during practical use.

3. Design and Simulation

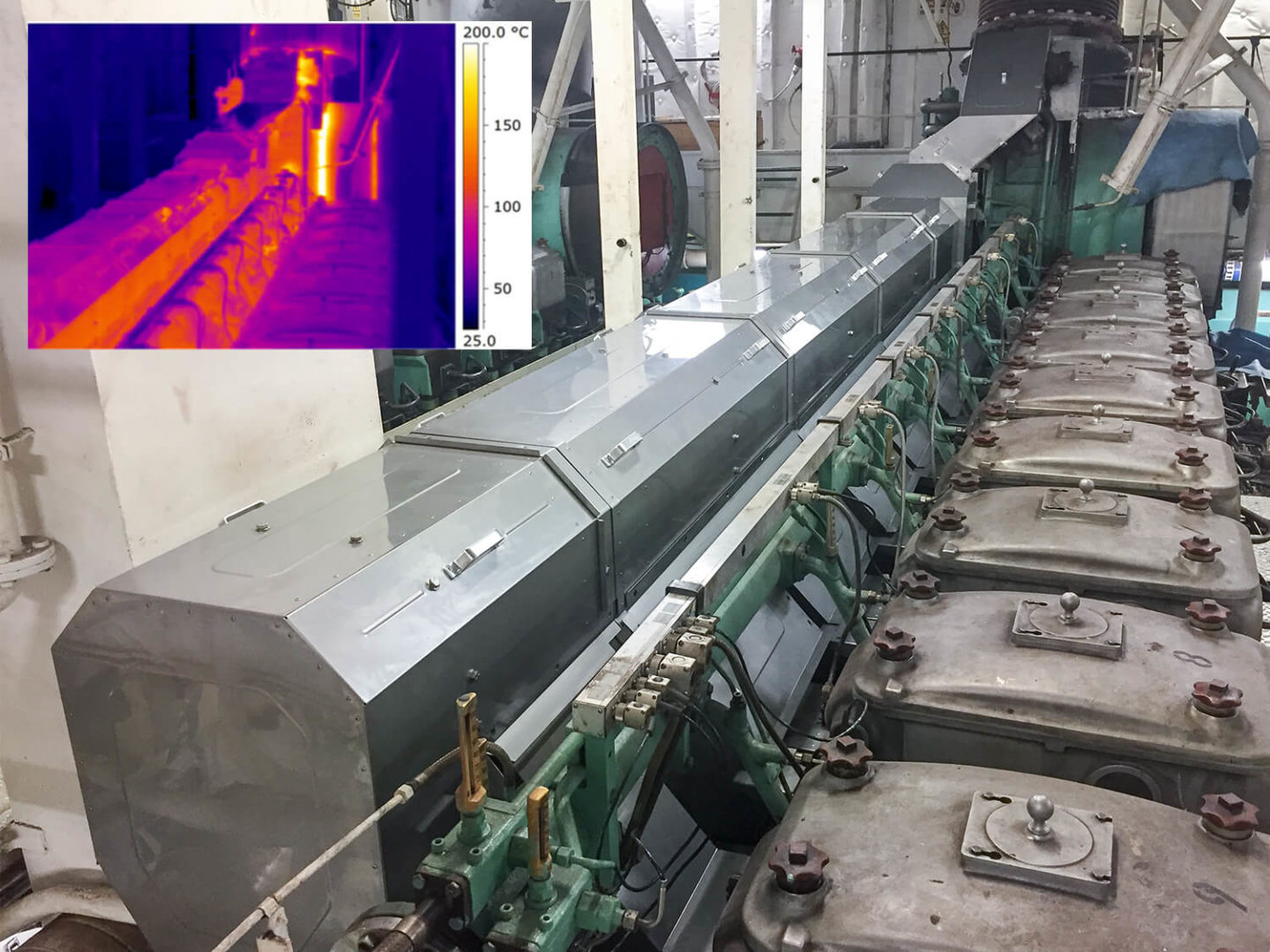

Once the design and simulations are complete, our specialists assemble the prototype exhaust/turbocharger cladding directly onto your engine.

At the end of the development work, they will also perform a thermography during engine operation. This allows any existing hotspots to be localized and fixed in a timely manner.

Do you have questions?

We have the right answers

- Efficiency increase

Retrofitting with modern high-temperature insulation from tmax can significantly improve the performance and efficiency of engines and equipment. - Cost reduction

Another significant advantage of retrofitting is the reduction of operating costs. By using state-of-the-art insulation, energy and material consumption can be reduced, resulting in significant cost reductions. - Service life extension

RETROFIT measures extend the service life of existing engines by reducing wear and tear. This leads to higher efficiency and better use of resources. - Sustainability

Retrofitting contributes to sustainability by reducing the energy consumption and environmental impact. It also makes it possible to comply with legal requirements and environmental regulations.

No. If 3D data is not available, it can be collected using our unique mobile 3D technology. We also use this data to perform a wide variety of analyses and simulations in order to design and manufacture an insulation solution that is optimized for you.

Using a prototype insulating casing, a thermographic measurement is carried out together with the customer during a test bench run of the engine. Compliance with the specified surface temperatures and possible exceedances are determined and documented in a suitable manner with the customer. The resulting thermography report contains at least the following information of the engine test run: exhaust gas temperature before exhaust turbocharger, engine load and ambient temperature.

Yes, all the insulating cladding not only reduces the surface temperature, but also helps to significantly reduce the sound pressure level at the engine.

Let’s talk, we have the answers.

- Efficient fire protection for man and machine

- Temperature reduction to below 220 °C - down to 60 °C on request

- Protection of temperature-sensitive components from heat radiation

- Minimum additional weight

- Safety from machine failure

- Cheaper insurance premiums