Metal insulation cladding

No heat, no fire:

How metallic insulation cladding prevents fires

- Lifetime durability

- Insulation cladding from the market leader

- Easy assembly & maintenance

- Surface temperature to below 60 °C

Contents in this e-book

How to overcome all challenges in the high temperature range.

- What are high temperature insulations?

- Where are they used?

- Requirements for high temperature insulation

- Our insulation solutions: Metallic, Foil, Textile

- Around tmax: competencies and services

Our Insulation & Insulation Solutions Prevent Fires

Optimal touch & fire protection

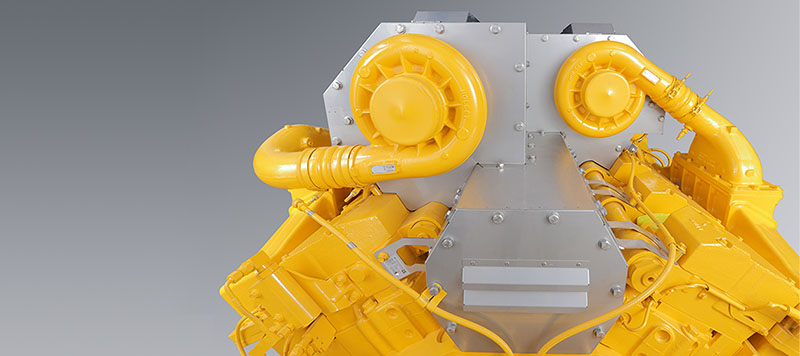

Most fires start in the engine compartment. The main cause of this is deposits that ignite when they come into contact with components such as the turbocharger, manifold and exhaust tract, with a surface temperature of up to 750 °C. Metallic insulating cladding reduces the surface temperature to below 220 °C,

even up to 60 °C if desired.

When the machine catches fire

Fire hazard in the engine compartment

Protect your commercial vehicles

The engine compartment contains both flammable materials and extremely hot surfaces of up to 750 °C. About 50 percent of all fires in the engine compartment are caused by leaks. This can cause flammable liquids to drip onto hot surfaces and ignite. Hydraulic oils already ignite at a temperature of 250 °C.

The second most common cause of fire is electrical short circuits, followed by combustible materials coming into contact with hot surfaces.

If a fire occurs, human lives are in serious danger. At the same time, a breakdown of commercial vehicles always means a loss of productivity.

A prevented fire does not have to be extinguished

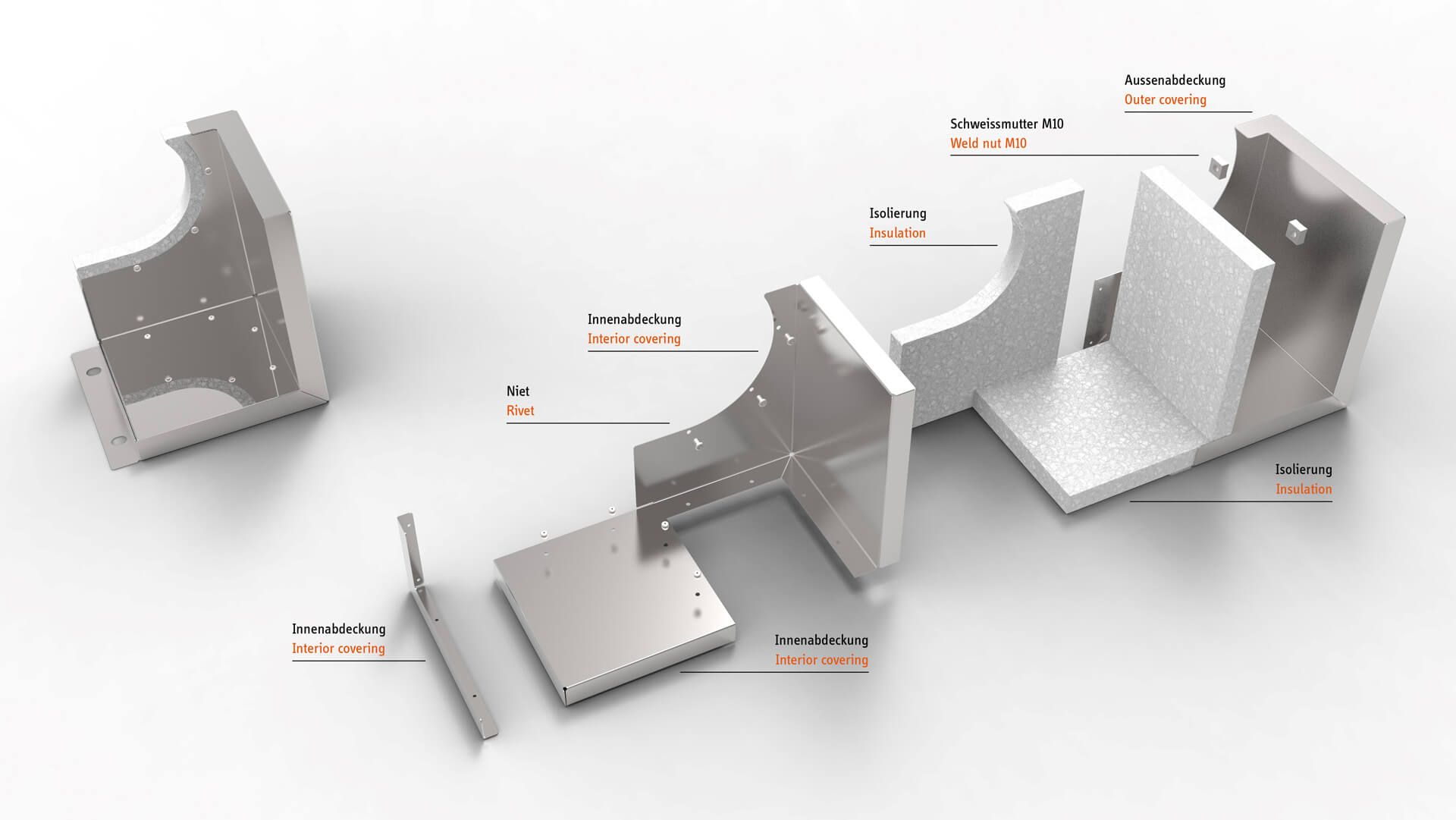

Functionality of metallic insulating cladding

A metallic insulating cladding consists of three

components in cassette design: the outer sheet, the insulating material and the inner sheet. It encases the component to be insulated and significantly reduces the hot surface temperatures that are not unusual for the engine compartment.

With tmax insulating cladding, a maximum of 220 °C prevail, where it would normally be up to 750 °C. Even only up to 60 °C, if requested.

This meets the strict temperature requirements of the SOLAS (Safety of Life at Sea) directive – an international agreement for the protection of human life on the high seas that has been in force since 1974.

Flammable deposits, oils, and fuels can no longer settle directly on the hot surfaces, and temperature-sensitive components in the vicinity are protected from overheating.

Manufactured using the latest metalworking processes, tmax insulating cladding can be tailored precisely to the requirements of individual machines and motors. The torsionally rigid and vibration-resistant components master the high mechanical requirements in the engine compartment and are easy to assemble and disassemble.

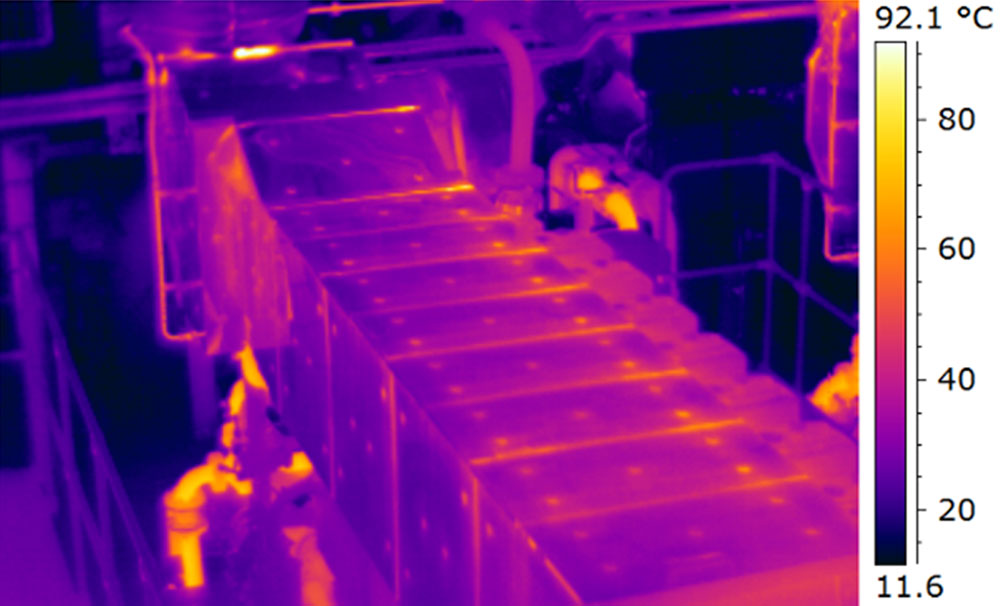

The proof: fire protection of the highest quality

Tmax insulation cladding in thermography

With over 45 years of experience as a solution provider in high-temperature insulation, tmax has been able to build a sophisticated research laboratory. In this laboratory, we can prove that our products deliver what they promise by using the latest technologies and broad technical know-how. This includes thermography carried out with our own equipment, which clearly proves that the surface temperatures of temperature-sensitive components are protected from overheating.

Flammable deposits no longer catch fire. The reliability and cost-effectiveness of the machine are increased.

Do you have any questions?

We have the right answers

Depending on your requirements.

Vibrations and oscillations of engine components must be given special consideration during product design. Quiet fastening points are important for optimal fastening of the insulating cladding. However, if this is not possible, the cladding parts must be decoupled accordingly.

Yes, all the insulating cladding not only reduces the surface temperature, but also helps to significantly reduce the sound pressure level at the engine.

No. If 3D data is not available, it can be collected using our unique mobile 3D technology. We also use this data to perform a wide variety of analyses and simulations in order to design and manufacture an insulation solution that is optimized for you.

Using a prototype insulating casing, a thermographic measurement is carried out together with the customer during a test bench run of the engine. Compliance with the specified surface temperatures and possible exceedances are determined and documented in a suitable manner with the customer. The resulting thermography report contains at least the following information of the engine test run: exhaust gas temperature before exhaust turbocharger, engine load and ambient temperature.

Let’s talk, we have the answers.

- Efficient fire protection for man and machine

- Temperature reduction to below 220 °C - down to 60 °C on request

- Protection of temperature-sensitive components from heat radiation

- Minimum additional weight

- Safety from machine failure

- Cheaper insurance premiums