Optimal temperature control and sound insulation for trucks

Whether it’s an increase in engine efficiency, reliable exhaust gas aftertreatment or effective noise protection – our insulation solutions make a decisive contribution to optimizing your trucks.

More efficiency

Better values

tmax: the expert for

high-temperature insulation for trucks

Ensure efficient exhaust aftertreatment and reduce the thermal risk of your vehicles with insulation solutions from tmax. Also available as RETROFIT for older engines.

Fulfillment of exhaust emission standard

Increased efficiency

Heat protection of surrounding components

Soundproofing

Contents in this e-book

How to overcome all challenges in the high temperature range.

- What are high temperature insulations?

- Where are they used?

- Requirements for high temperature insulation

- Our insulation solutions: Metallic, Foil, Textile

- Around tmax: competencies and services

Meet guidelines

Increase protection

Increase efficiency

Whether it's an increase in engine efficiency, reliable exhaust gas aftertreatment or effective noise control – our solutions make a decisive contribution

Insulation systems for engine and exhaust tract

Meet emission standards

Emission standards for trucks are becoming increasingly stringent. To ensure that these requirements can be met, efficient exhaust gas aftertreatment, reduced fuel consumption and effective noise control are indispensable measures.

At tmax, we develop and produce highly effective thermal and acoustic insulation solutions for trucks that meet the requirements of the future

- Effective exhaust gas aftertreatment

- Compliance with emission standards

- Reduction in consumption / increase in efficiency

- Optimal fire and personnel protection

- Effective sound absorption

- Protection of surrounding components

- Increased service life of your machines

Commercial vehicles of the future

Efficient, clean, and quiet

Commercial vehicles are versatile and flexible. There is a tailored concept for every transport need: buses for passenger transport, distribution vehicles for supplying city centers, or vans and heavy trucks for long-distance transport.

The increasingly stringent requirements of the legislature present vehicle manufacturers with complex challenges. Currently, the EURO 6 / EURO 7 emission guidelines and EU Regulation 540/2014 on noise emissions apply to trucks. In addition, there is increasing pressure from consumers and politicians to offer new drive technologies such as lithium-ion battery systems, fuel cells or hydrogen engines.

In addition, the efficiency of trucks must be increased and cost-effectiveness ensured.

The good news is: thermal and acoustic insulation systems from tmax make a decisive contribution to the

- reduction of pollutant and noise emissions and thus compliance with emission guidelines

- Reduction of fuel consumption and

- increase in efficiency.

Avoid energy loss directly at the source

Efficient exhaust gas aftertreatment with tmax insulation solutions

Thermal insulation from tmax maintains the necessary process heat within the system (turbocharger, manifold, exhaust tract, DPF, SCR, …), thus making a decisive contribution to more efficient exhaust gas aftertreatment.

The effective prevention of energy loss in the exhaust tract offers the following advantages:

- Prevention of urea crystallization: Heat retention prevents crystals from forming in the diffuser area and reducing the effectiveness of exhaust gas cleaning.

- Improved light-off behavior: Optimum temperatures in the exhaust gas aftertreatment system are reached significantly faster, exhaust gas aftertreatment works earlier and better, resulting in better exhaust gas values.

Hydrogen engines: The future has a heat problem, tmax the solution

The world has a goal of ZERO CO₂ emissions. The future is a mix of engines using different fuels. Hydrogen drives play a major role here. In the near future, production-ready engines will find their way into the mass market.

And tmax is a part of it, with proven excellent results in increasing efficiency.

As the industry leader in intelligent insulation and insulating solutions for the hydrogen market, we increase the efficiency of hydrogen engines, turbochargers, and manifolds – also for trucks.

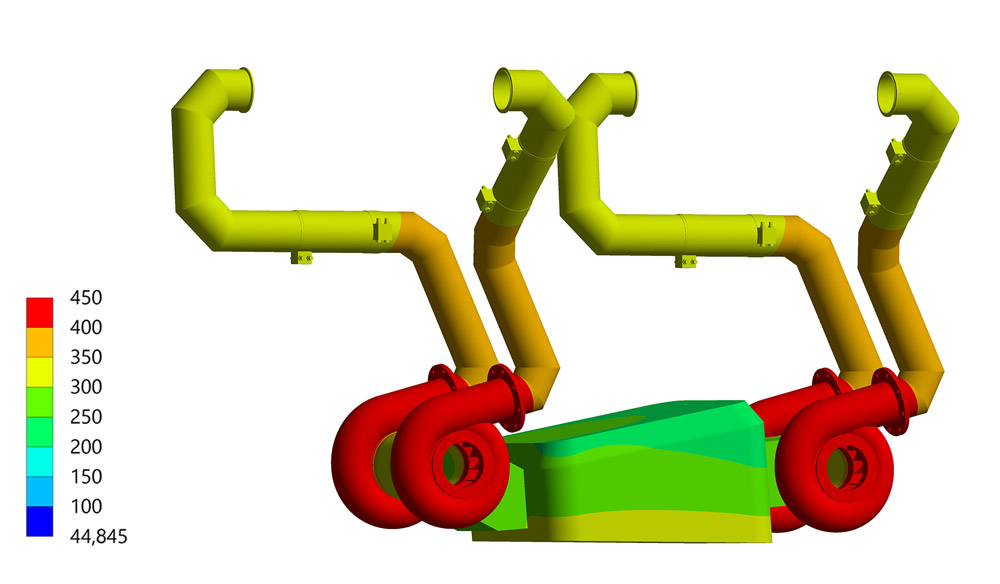

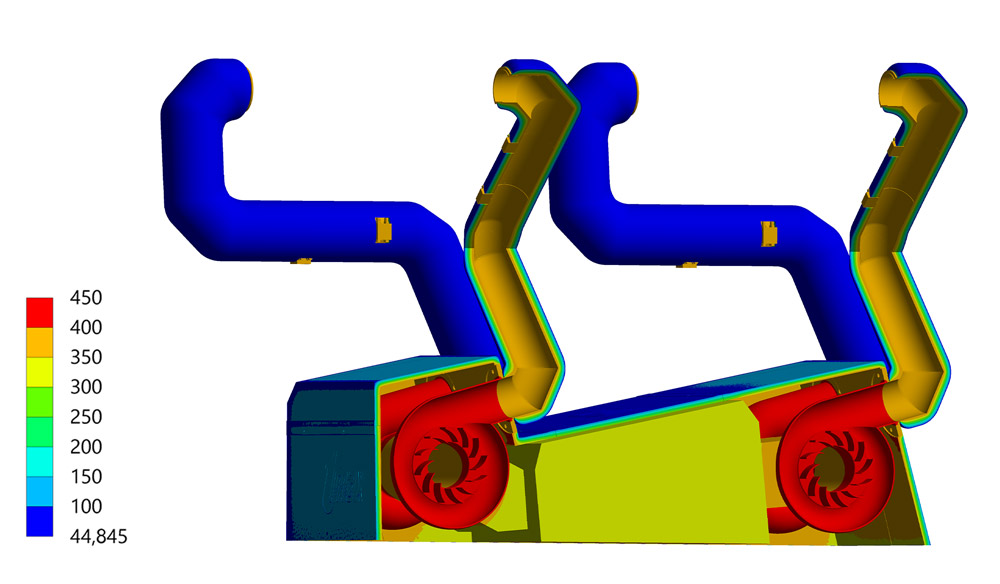

More simulations, fewer prototype cycles, lower costs

Developing new products takes time, but it doesn't have to

Unique in the industry: tmax simulations save you endless loops in the development process.

- Find thermal weak points

- Vibration simulation for predicting the behavior of a virtual component

- Simulation for the evaluation of concepts and designs

This way we can identify and eliminate weak points and shorten development times and reduce unforeseen costs, even before a prototype is produced.

We have something against water

The first high-temperature insulation that also protects against water

In wet weather or during engine washing, insulation fibers can easily become saturated with water. The result is a delayed light-off behavior, as the system loses valuable heat as the fiber dries. In this phase, consumption and emissions from a truck are particularly high. In addition, the durability of the insulation deteriorates because salt and dirt particles penetrate the fiber along with the water and are deposited there after evaporation.

- Compliance with emission standards

- Effective reduction of consumption

- Easy assembly and disassembly

tmax-DryTec is applicable to all tmax fibers.

Download

In the on-highway industry, optimum temperature control and sound attenuation must be combined with high durability and ideal maintenance conditions.

Download

In the 2019 article at ATZ Heavy Duty, tmax appendix of different tests, shows the safety and effectiveness of the innovative battery case.

Download

The emission directives (Euro 6) in the on-highway sector are constantly becoming more stringent.

The good news is: thermal and acoustic insulation systems from tmax make a decisive contribution.