With the launch of the Turbine Insulation business in June 2018, Thermamax is expanding its gas and steam turbine activities with the aim of proactively driving the company’s growth – particularly in the North American market.

In the field of stationary energy generation, Thermamax is already successful with its insulation systems. Now, the company is expanding its product portfolio and offering a comprehensive package of solutions in the field of gas turbines with a capacity of up to 560 MW and steam turbines up to and beyond 1 GW. In this way, Thermamax intends to exploit the great market potential, especially in the USA, and thus continue to grow.

In order to pursue this project, the Turbine Insulation business unit at Thermamax in Mannheim was founded at the beginning of June 2018. Project management and product development take place at the headquarters in Germany, under the leadership of Andreas Riedinger. On the sales side, the team is supported by the team of Thermamax, Inc. in the USA. The newly developed insulation systems will be manufactured in the USA and assembled in cooperation with local specialists. This way, the local content requirements of North American customers will be met. The focus of this new offering – in addition to the custom-fit insulation solution – is the service and accessibility of the Thermamax team on site.

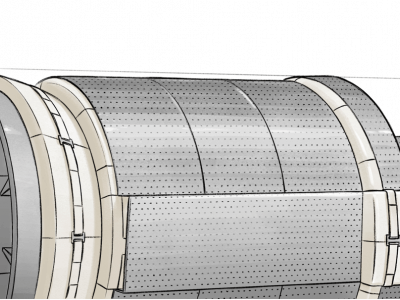

Gas and steam turbines in combined-cycle power plants (CCPP) ensure a stable and secure power supply. Due to their size, the existing high-temperature conditions of up to 700 °C, the strong vibrations and the need for mounting inserts that are as short as possible, they place high demands on insulation.

The newly launched offering consists of a sophisticated high-end insulation system tailored to the geometry of the turbine in question and a comprehensive service package that can be put together individually, depending on customer requirements and needs.

Compared to conventional systems, Thermamax’s single-layer insulations offer significantly higher insulation performance and service life, and reduce maintenance requirements to a minimum. The service around the product ranges from the assessment of findings by means of thermography, to the installation of the individually developed insulation system as well as maintenance, depending on the requirements.

Not only turbine manufacturers are addressed, but also power plant operators who need to have their aging insulation replaced.

The first sales success has already been recorded: Thermamax was commissioned to insulate a section of a gas turbine for a power plant in the USA. Overall, interest in the Thermamax product and service is high.

Thermamax, Inc. President Dirk Balthasar is satisfied: “With the establishment of the Turbine Insulation business unit and the newly developed product and service package, we have gained access to a new market segment and thus reached an important milestone in the implementation of our growth strategy.”

Learn more about tmax gas turbine insulation here.