Properly insulate turbocharger

The turbocharger compresses the combustion air supplied to the engine, thereby ensuring more efficient combustion and more power with the same fuel consumption. Turbocharger insulation enhances this effect and at the same time brings further benefits in terms of greater occupational safety, fire protection and improved emission values.

It is not uncommon for the exhaust side of the turbocharger to reach temperatures of over 1,000 °C, which pose a danger to people, machines, and the economy. With turbocharger insulation, risks can be minimized and, in addition, efficiency can be increased and better emission values achieved.

Small, medium and large turbochargers

Three different high temperature solutions

for different industries and applications

A wide product range of different insulation and insulating materials makes it possible to solve any challenge in the high-temperature range.

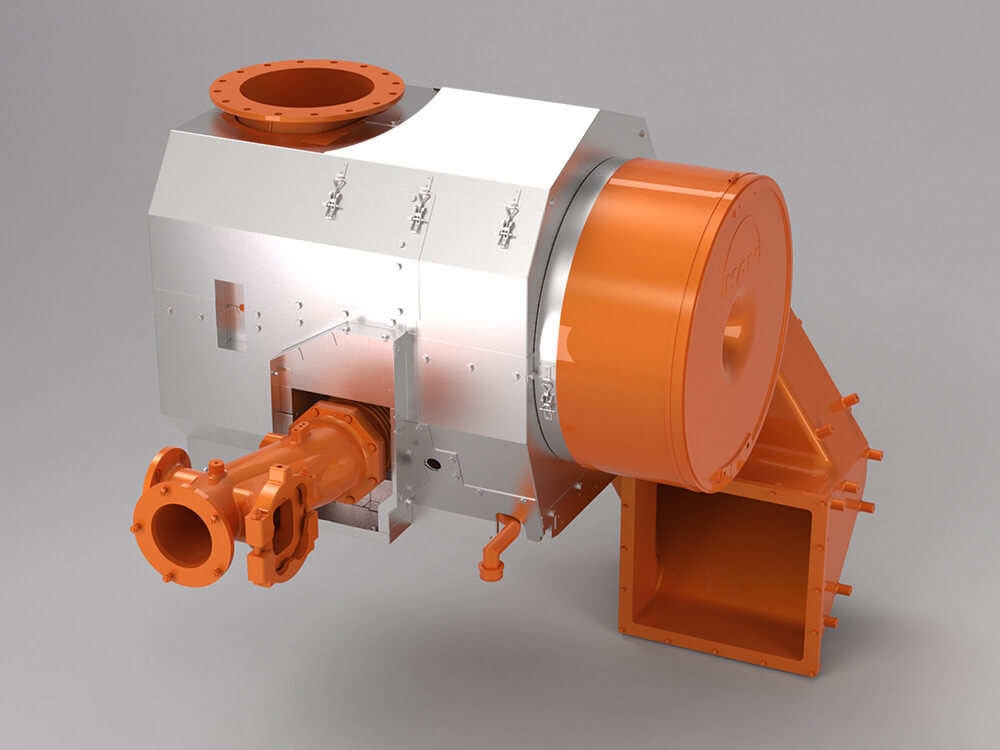

Metal turbocharger

Insulation

- High insulation value

- High durability

- Self-supporting construction

- Easy assembly

- Ease of maintenance

Use in industries

- Marine

- Industry

- Off-Highway

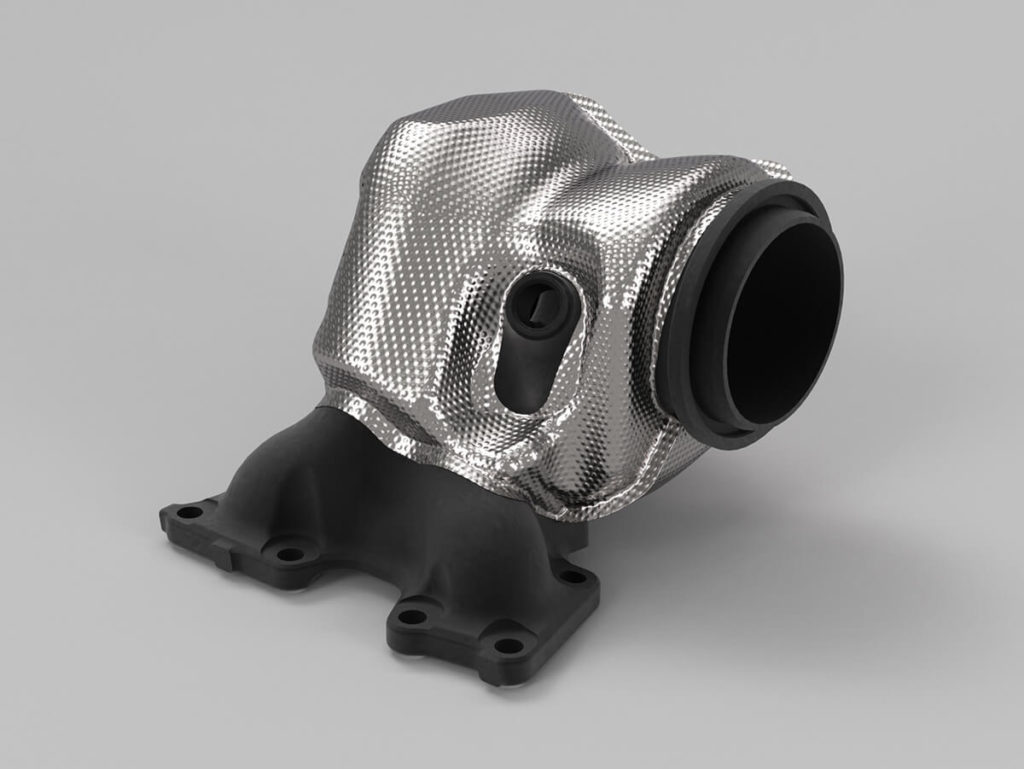

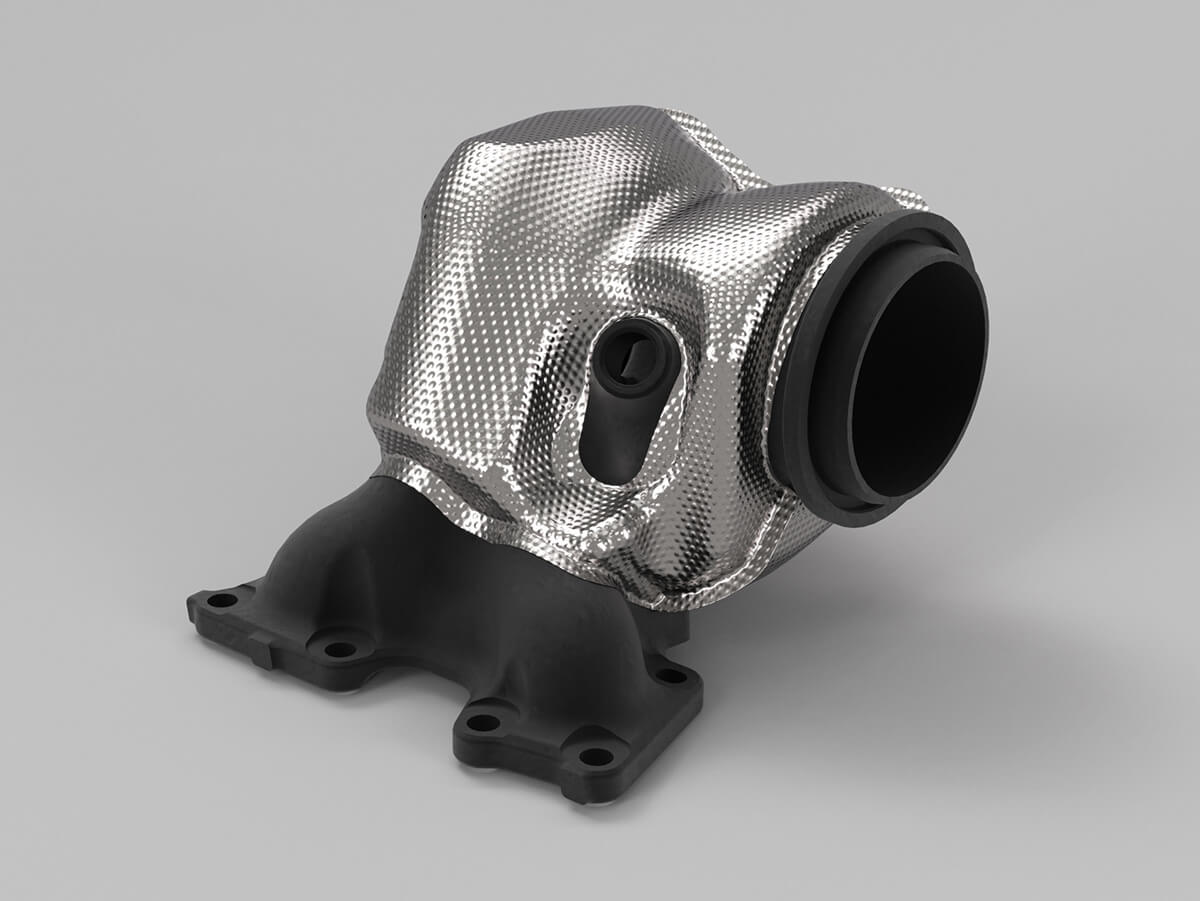

Foils turbocharger

Insulation

- Precisely fitted to the component,

for complex building tail geometries - Light weight and space saving

- Optional: Water repellent insulation material

- Optional: Reinforced sound insulation

Use in industries

- Automotive

- Motorsport

- Truck & Bus

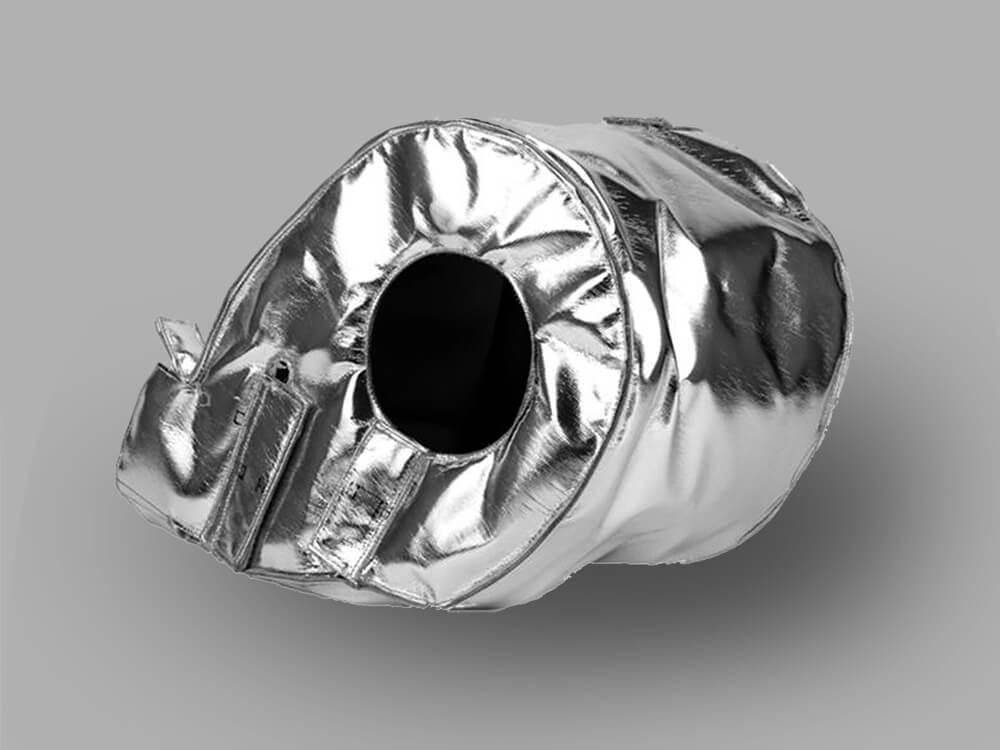

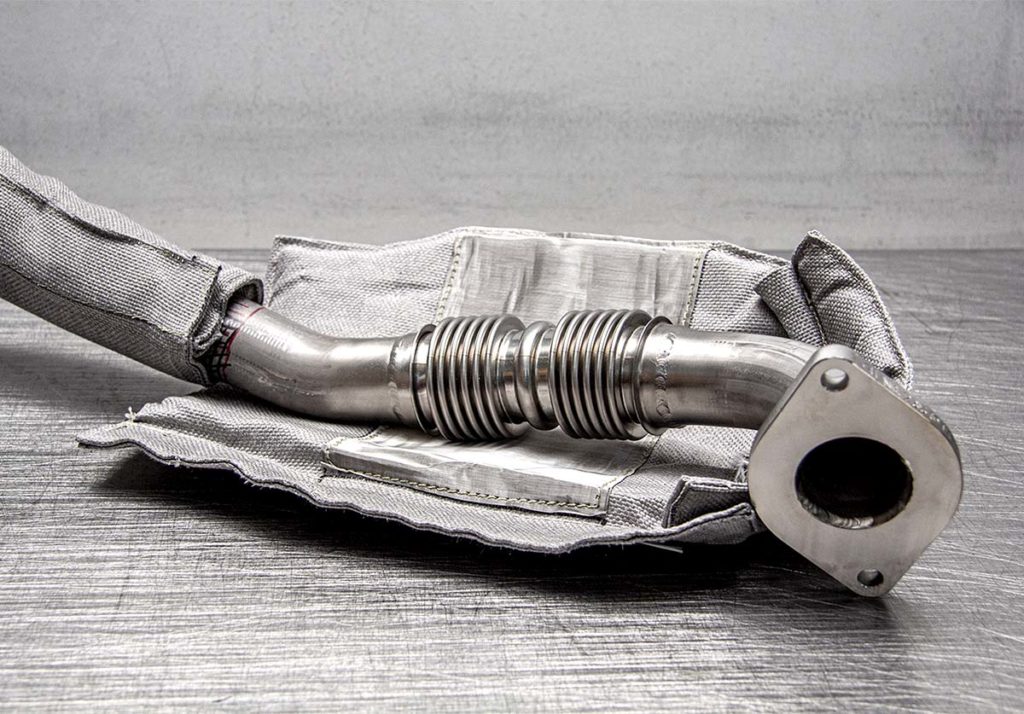

Textile turbocharger

Insulation

- Simple to complex insulation solutions

- Perfect touch protection

- Quick assembly and disassembly

- Short development times

- Low tooling costs

Use in industries

- Marine

- Industry

- On-Highway

Maximum temperatures under control

The advantages of metallic turbocharger insulation

Fires often start in the engine compartment, where there are very high temperatures as well as highly combustible materials and debris. With tmax insulating cladding, optimum fire protection as well as burst and explosion protection is guaranteed, protecting man and machine from breakdowns.

Metallic turbocharger insulation reduces the surface temperature of all components to below 200 °C; on request even down to 60 °C.

But that is not all. Added to this are improved emission values, extended service life and high service and maintenance friendliness.

360° view of a turbocharger with metallic cladding. With the off or finger movable.

Precise fit for optimum insulation protection

The advantages of tmax foil turbocharger insulation

In the automotive and on-highway sectors in particular, it makes sense to insulate turbochargers with space-saving and ultra-light insulation made of stainless-steel foil.

Our foil insulation makes a decisive contribution to increasing the efficiency of your turbocharger. The foil insulations fit around the highly complex outer contours of the turbocharger to be insulated with millimeter precision, and likewise increase the reliability and extend the service life of the surrounding components.

Best suited for high temperatures

The advantages of tmax Textile turbocharger insulation

The Textile Insulation is a removable multi-component insulation shell made of technical fabrics with incorporated insulation material. Due to the flexibility of the insulating moldings, it offers maximum individual, precision-fit fabrication.

This results in advantages such as minimizing the heat-up time of the turbocharger and, in the marine industry, meeting SOLAS guidelines.

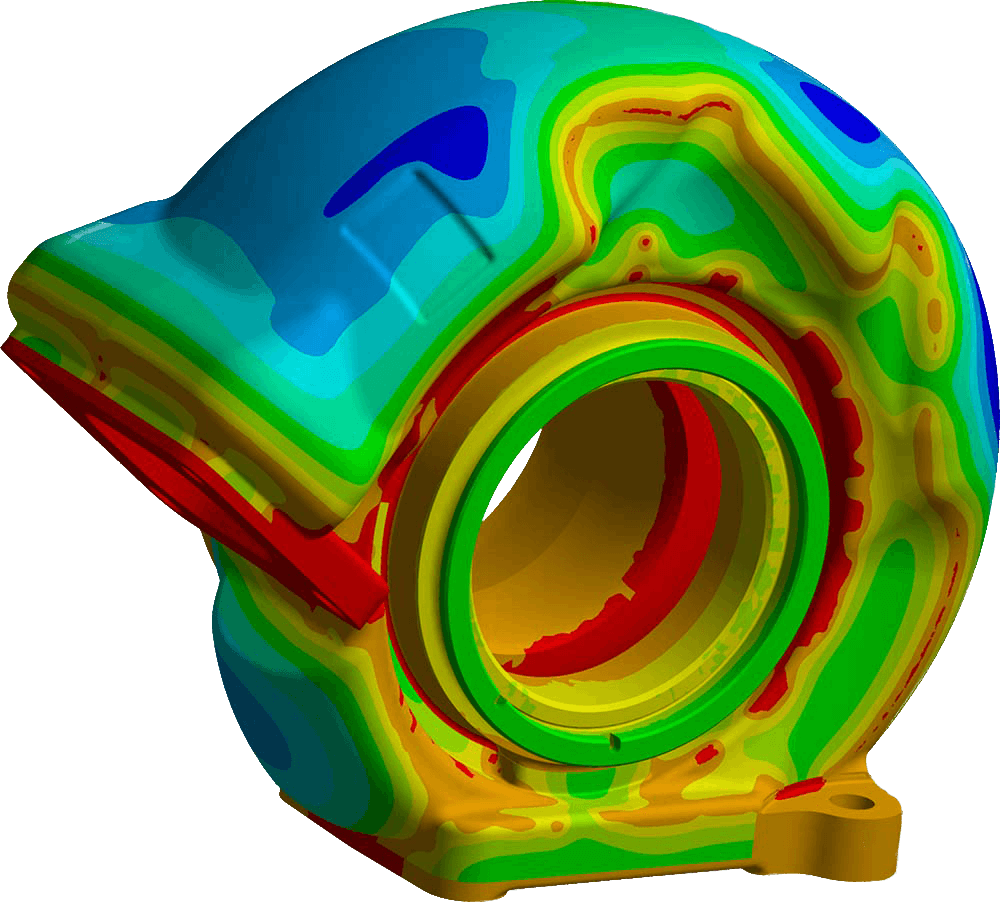

The proof – tmax insulation reliably reduces the temperature

Temperature analysis of an isolated turbocharger

With over 45 years of experience as a solution provider in high-temperature insulation, tmax has been able to build a highly sophisticated development and testing laboratory. In this laboratory, we can prove that our products deliver what they promise by using the latest technologies and broad technical know-how.

Our temperature simulation is used to determine temperatures at the surfaces of the insulation cladding, to be able to estimate whether the selected insulation configuration meets the required customer and legal specifications.

Do you have any questions?

We have the right answers

Different areas of an exhaust system can experience different levels of vibration. Rigid insulation at the interface can quickly wear out as a result.

We offer you individual, flexible insulation solutions for a clean interface, which are designed to insulate optimally even with varying vibration behavior and manage to compensate for vibrations and thermal expansion.

Yes – tmax insulation solutions are particularly easy to service and maintain. Customer requirements are always taken into account as early as the design and construction stage.

Possibly. Experience has shown that tmax insulation can be a factor in lower insurance premiums. The insulation serves as an additional, upstream fire protection measure. It increases reliability and reduces the risk of fire and explosion, so it can prevent expensive damage, downtime and standing costs.

Yes, the entire insulating cladding not only reduces the surface temperature, but also helps to significantly reduce the sound pressure level of the turbocharger and especially the compressor.

Download

Comply with SOLAS regulations and IMO emission standards, optimize fire protection in a targeted manner.

Almost all leading companies in the marine sector use the know-how and technologies of the tmax brand. Learn what makes the leader in SOLAS insulation.

Download

Successful insulation concepts for passenger cars. From new development to series production.

Suitable for temperature requirement to support exhaust aftertreatment, protect surrounding components and reduce engine compartment temperatures.

Download

Insulation technologies

for off-highway vehicles.

When high-horsepower engines operate safely and efficiently off-highway and easily comply with valid emission standards, it usually means that creative solutions from tmax are involved.