Patented safety valve for lithium-ion battery housing

The use of lithium-ion batteries is associated with high thermal

risks. Therefore, the general safety in case of fire plays an essential role. With the newly developed and patented pressure equalization, pressure overload valve (DAÜ valve), tmax provides increased fire protection if a so-called thermal breakthrough occurs. For example, in the event of a fire inside the enclosure, thus helping to minimize the thermal risk.

Features

- Maximum safety in the event of an accident

- Fire resistant

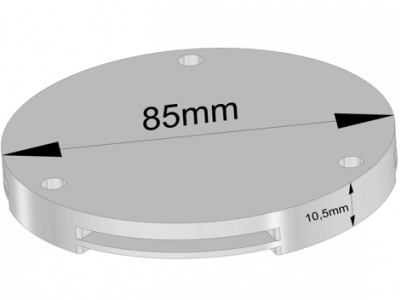

- Bursting pressure 0.3 bar | variably adjustable

- Tolerance of the bursting pressure +/- 10%

- System tightness according to IP code: IP-67 and IP-6k9k

- High EMC shielding

- 4 patents filed for the tmax safety valve

- No tooling costs

All info at one glance. Download PDF now.

The requirement for a safety valve

Protection in case of pressure equalization and overload

Since lithium-ion batteries are currently manufactured primarily with oxide cathode material due to the high charge density, a fire once ignited will henceforth supply itself with oxygen. This continues to burn even in the closed case, creating the risk of propagation, i.e., ignition of other, neighboring battery cells.

Without constructive measures, the pressure generated in the housing becomes too high, there is a risk of bursting or failure of sealing systems, and the highly toxic fumes can escape in an uncontrolled manner. The valve prevents this; at a defined overpressure, the flue gases are released into the environment in a controlled manner. Due to the high temperatures that occur, the basic structure of the valve is fireproof.

The solution: A safety pressure compensation, pressure overload valve (DAÜ valve)

The implemented design principle ensures a very small tolerance of the individually designed burst pressure (from 250mbar). The DAÜ valve is also characterized by a compact design and meets the protection class IP-67 and IP-6k9k. All individual components are manufactured without specific tooling, and the airflow and bursting pressure parameters can thus be scaled in a simple manner via adjustments to the geometry. Even smaller quantities can thus be produced without tooling cost surcharges. The metallic design ensures optimum EMC shielding and allows an optional connection for guided smoke degassing via a connected duct system. The use of a semi-permeable membrane compensates for the natural expansion of heat during charging and discharging of the battery and the atmospheric pressure variations of the environments.

How does the safety valve work?

The pressure overload function (bursting function) is realized utilizing a rupture disc. When the pressure in the body becomes too high, the interaction between the diaphragm and the rupture disc allows the valve to open. This allows the pressurized gas to escape from the housing in a controlled manner. The labyrinthine design also ensures that in the event of a fire, the escape, or spread of flames is greatly reduced. The functionality of the system was tested in tmax’s own R&D laboratory. The variability of the burst pressure setting options, their narrow tolerance as well as the protection class could be confirmed accordingly. The system was patented.

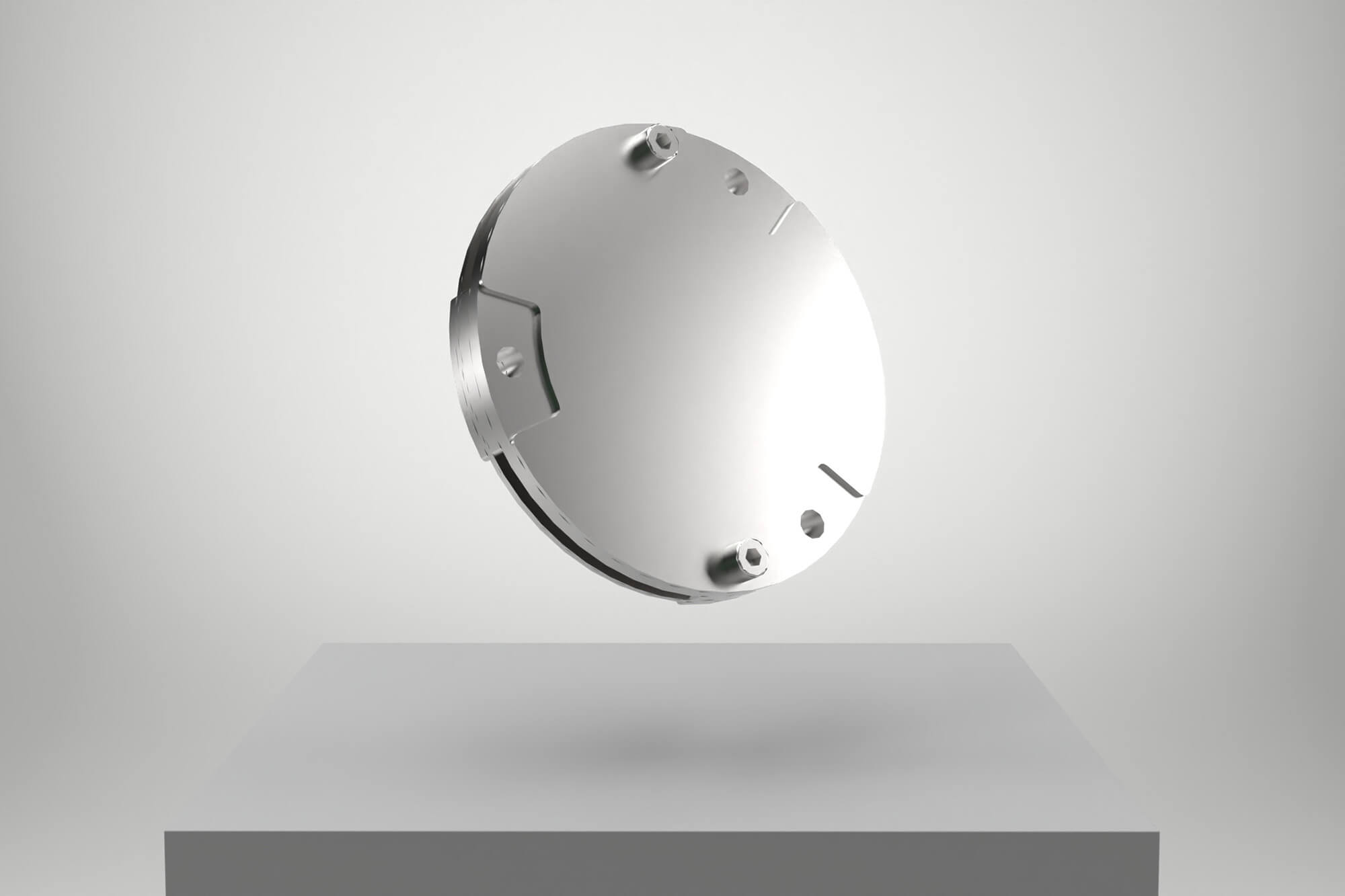

360° view of a stainless steel safety valve. With the mouse off or finger movable.

Extension: valve with exhaust adapter

An exhaust adapter forms the interface to a vent pipe in order to remove the toxic gases in a controlled manner during thermal run-through.

Variant: Central outflow direction

All this and more: we, at tmax, have developed another safety valve variant that directs the escaping toxic gases in a desired alternative discharge direction.

Blog

The use of lithium-ion batteries is associated with high thermal risks. Therefore, general safety in the event of fire plays an essential role in the development of battery enclosures.

Download

In the 2019 article at ATZ Heavy Duty, tmax appendix of different tests, shows the safety and effectiveness of the innovative battery case.

Download

All important information and exciting insights about the high-temperature resistant battery housing for lithium-ion systems at a glance. To read, share or print.