Insulate your exhaust pipe

with insulation solutions from the market leader

Exhaust pipes are an important part of the exhaust system. They guide harmful exhaust gases from the engine’s combustion chamber safely through the exhaust system and finally discharge them. Due to their field of application, they are permanently exposed to high mechanical stresses, high temperatures and extreme temperature fluctuations.

To ensure smooth operation, exhaust pipes must be insulated to suit the specific application. Our tmax solutions ensure that optimum temperatures prevail at all points in the exhaust tract and that the surrounding periphery is protected.

Maintaining optimum exhaust gas temperatures optimizes the heating behavior of the exhaust aftertreatment systems (light off), reduces temperature fluctuations in the system during changing operating behavior, and thus increases the efficiency of the exhaust system. It also protects surrounding components from high temperatures and provides corresponding effective fire and contact protection.

The perfect exhaust pipe insulation for every challenge

Three different high temperature solutions

for different industries and applications

A wide product range of different insulation and insulating materials makes it possible to solve any challenge in the high-temperature range.

Metal exhaust pipe

Insulation

- High insulation value

- High durability

- Self-supporting construction

- Easy assembly

- Ease of maintenance

Use in industries

- Marine

- Industry

- Off-Highway

Foils exhaust pipe

Insulation

- Precisely fitted to the component,

for complex component geometries - Light weight and space-saving

- Optional: Water repellent insulation material

- Optional: Reinforced sound insulation

Use in industries

- Automotive

- Motorsport

- Truck & Bus

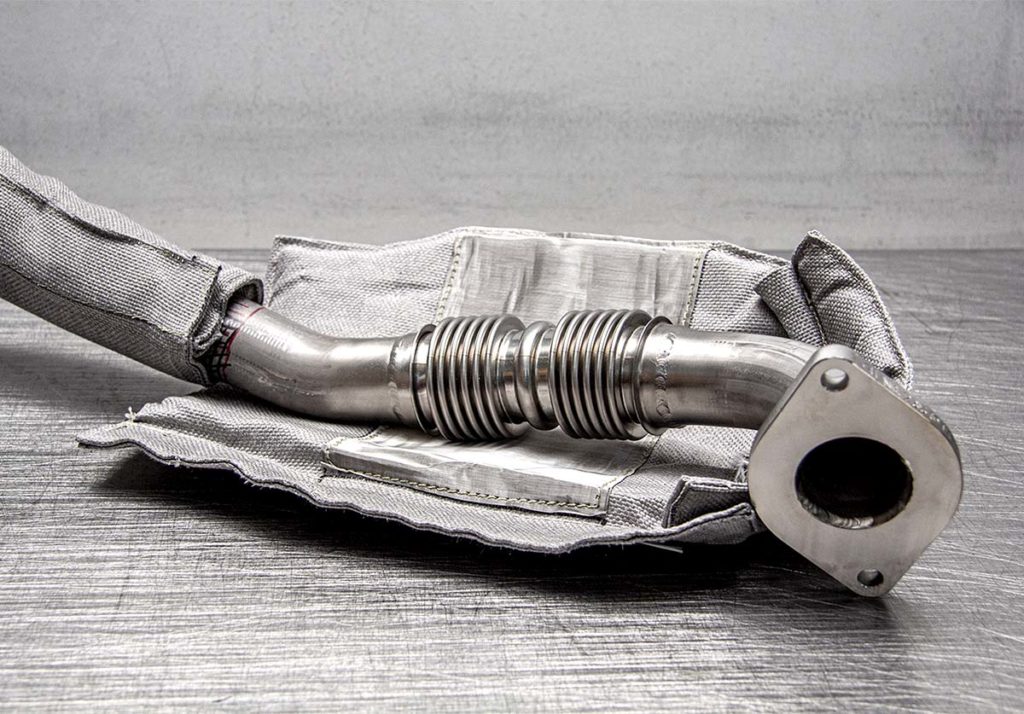

Textile exhaust pipe

Insulation

- Simple to complex insulation solutions

- Perfect touch protection

- Quick assembly and disassembly

- Short development times

- No tooling costs

Use in industries

- Marine

- Industry

- On-Highway

Efficient exhaust gas aftertreatment for large & small engines

The EU environmental protection likes that

The emission standards for internal combustion engines, set by legislators, are becoming increasingly stringent. This means that engine developers are constantly facing new challenges. For this reason, innovations are in high demand. Efficient exhaust gas aftertreatment depends on optimum temperature distribution in the system. The bottom line is that a tmax solution ensures that optimum temperatures prevail at all key points in the exhaust tract. In this way, they contribute to compliance with legally prescribed exhaust gas values. To meet emission standards, tmax develops and produces numerous custom-fit solutions for all series sizes. The combination of different tmax insulation systems and the use of state-of-the-art insulation materials, in particular, achieves values that were previously hardly imaginable.

Maximum temperatures under control

The advantages of a metal exhaust pipe

Insulation

Fires often start in the engine compartment, where there are very high temperatures as well as highly combustible materials and debris. With tmax insulating cladding, optimum fire protection as well as burst and explosion protection is guaranteed, protecting man and machine from breakdowns.

Metallic turbocharger insulation reduces the surface temperature of all components to below 200 °C; on request even down to 60 °C.

But that is not all. Added to this are improved emission values, extended service life and high service and maintenance friendliness.

360° view of an exhaust system with metallic cladding. Movable with the "mouse" or finger (tablet/mobile).

Precise fit for optimum insulation protection

The advantages of a tmax foil exhaust pipe

Insulation

In the automotive and on-highway sectors in particular, it makes sense to insulate exhaust pipes with a space-saving and ultra-light insulation made of stainless-steel foil.

Our foil insulation makes a decisive contribution to increasing the efficiency of exhaust gas aftertreatment. The foil insulations fit around the highly complex outer contours of the exhaust pipe to be insulated with millimeter precision and also offer not only efficient fire protection, but also increase the reliability and extend the service life of the surrounding components.

Best suited for high temperatures

The advantages of a tmax Textile exhaust pipe

Insulation

The Textile Insulation is a removable multi-component insulation shell made of technical fabrics with incorporated insulation material. Due to the flexibility of the insulating molding, it offers maximum accuracy of fit and individual customization.

This results in advantages such as the reduction of energy consumption and heat losses, as well as a minimization of heating times. In addition, the textile insulation ensures that the optimum conditions for exhaust gas purification prevail at all times at the critical points, and temperature-sensitive components are protected from heat input.

Do you have any questions?

We have the right answers

To meet the increasingly stringent requirements of the legislature, various systems can be used for exhaust gas aftertreatment. In particular, these include exhaust gas recirculation (EGR), exhaust gas aftertreatment with selective catalytic reduction (SCR) with the addition of AdBlue/Urea, or oxidation catalysts (DOC), which reduce particulate emissions from diesel engines.

- Reduced fuel consumption

- Improved light-off behavior

- Reduced emissions of carbon dioxide, soot particles and nitrogen oxides

- Protection of surrounding components

Consequently, the correct handling of high temperatures is becoming increasingly important. Thanks to tmax integral insulation, optimum temperatures prevail at all points in the exhaust tract – in short, maximum efficiency in exhaust gas aftertreatment.

Download

Comply with SOLAS regulations and IMO emission standards, optimize fire protection in a targeted manner.

Almost all leading companies in the marine sector use the know-how and technologies of the tmax brand. Learn what makes the leader in SOLAS insulation.

Download

Successful insulation concepts for passenger cars. From new development to series production.

Suitable for temperature requirement to support exhaust aftertreatment, protect surrounding components and reduce engine compartment temperatures.

Download

Insulation technologies

for off-highway vehicles.

When high-horsepower engines operate safely and efficiently off-highway and easily comply with valid emission standards, it usually means that creative solutions from tmax are involved.