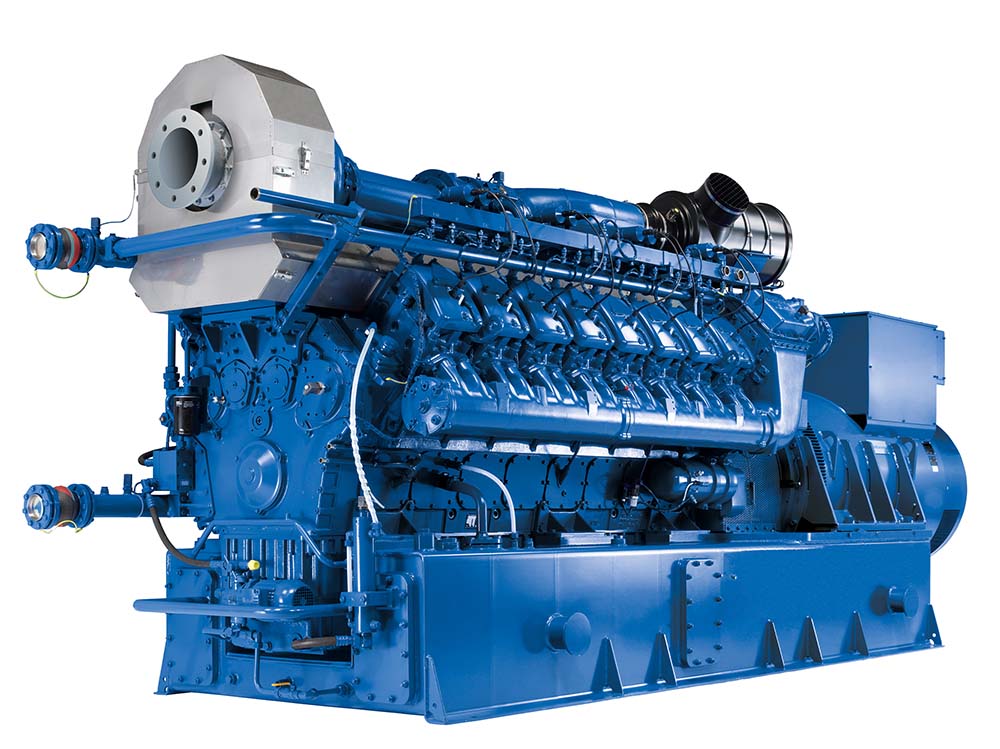

Insulation technologies for power generation with diesel and gas generators

Whether efficient exhaust gas aftertreatment, reliable fire protection or effective sound insulation – our insulation solutions make a decisive contribution to increasing the efficiency of diesel and gas generators.

Innovative temperature control for diesel and gas generators

Massive forces, permanent full load requirements, noise protection and environmentally friendly combustion. Stationary power generation places greater demands on power units and people than almost any other field of application.

tmax insulation solutions combine temperature and silencing technologies to support standard-compliant combustion and optimum power output with ease of installation and durability

- Temperature reduction from 1000 °C to below 220 °C – even down to 60 °C, if requested

- increased efficiency

- optimized sound insulation

- high durability

- high ease of maintenance

- reduced life cycle costs

Want to learn more about Power Generation? Arrange a non-binding appointment.

Increase efficiency through more efficiency at full load

Outstandingly effective and economically viable thermal insulation systems are based on more factors than just the use of insulation materials to ensure protection against contact. For years, tmax’s highly efficient insulation technologies have also made important contributions to increasing the efficiency of stationary generators.

Custom-fit and optimal insulation of the housing can significantly reduce energy consumption and increase performance at the same time. The tmax insulating linings are used on the genset as an optimal complete solution for the exhaust tract and exhaust gas turbocharger and ensure a remarkable increase in efficiency through targeted temperature control.

Increase ease of maintenance through significantly simplified assembly and disassembly

The tmax insulating cladding used in the field of power generation is characterized by its exceptionally high ease of maintenance: Thanks to their intelligent bracket designs, our modules in the Power Generation can be easily mounted and dismounted. The torsion-resistant, vibration-resistant structure forms an effective protection for both your employees and your machines – in accordance with the specified guidelines and standards.

- Completely removable modules

- Highly stable constructions

- Practice-oriented bracket designs

- Simplified maintenance

Inhalte in diesem E-Book

Wie Sie alle Herausforderungen im Hochtemperaturbereich meistern.

- Was sind Hochtemperaturisolierungen?

- Wo werden sie eingesetzt?

- Anforderungen an eine Hochtemperaturisolierung

- Unsere Isolierlösungen: Metallisch, Folie, Textile

- Rund um tmax: Kompetenzen und Services

Increase protection

Increase efficiency

Efficient exhaust gas aftertreatment, reliable fire protection or effective sound insulation – our solutions are used in almost all engines from leading manufacturers

For years, tmax has been the undisputed technology leader for outstandingly effective and economically viable thermal insulation. Targeted temperature control optimizes the performance and

significantly increases efficiency.

The tmax insulating cladding used in the power generation sector is characterized by its exceptionally high ease of maintenance: Intelligent bracket designs make the modules easy to mount and dismount.

Stationary generators thrive on powerful engines and can generate a lot of noise in the high load range. Our modular insulation cladding not only delivers highly effective fire protection, but also brings the desired soundproofing effect.

The highly stable design and extremely simple assembly and disassembly of our solutions also sustainably reduce costs right from the start. This also applies to older engine concepts.

Uncompromisingly safe:

tmax RETROFIT

Precisely fitting insulation solutions, for older motors as well

Worn insulations increase the risk of fire and thus hazards to people, machinery, and image. There is a risk of long downtimes and increased insurance premiums. To remain economical, outdated insulation must be replaced.

However, especially in the case of older engines, 3D data of the engine is often not available, which has so far made it difficult to retrofit generators with high-performance insulation systems. With our unique mobile 3D technology, missing 3D data of the engine is no longer a challenge.

With the tmax RETROFIT all-in-one package, we offer you all services – from the creation of 3D data of your ship’s engine to thermography of the insulation system developed and installed for you – from a single source.

Area-wide heat protection

Discover thermal hotspots before they become a hazard

Thermal hotspots often go undetected and pose a high safety risk to people and machinery. A complete check of the machines and systems is therefore necessary.

With tmax temperature measurements using infrared thermoscanning cameras, we can identify surfaces with very high temperatures in engine parts, exhaust pipes and electrical equipment.

This will enable you to counteract in a targeted manner and avoid risky hotspots with tmax insulating cladding.

Download

The demands are high. This is precisely why insulation from tmax is the first choice for manufacturers and operators around the globe. They support standard-compliant combustion and optimum power output with ease of assembly and durability.

Download

tmax insulation solutions combine temperature and sound insulation for stationary power generation and thus support standard-compliant combustion as well as optimum power output, ease of installation and durability.

Download

100% SOLAS-compliant insulation systems for retrofitting.

With tmax RETROFIT, even older engines can now be smoothly equipped with high-temperature insulation

systems.