Better fire protection for rail vehicle through high-temperature insulation

Fire protection for trains and locomotives is a top priority in rail transport. Find out here how the right high-temperature insulation can reduce...

How does a high-temperature insulation work? What is important and which temperature reductions are possible?

A high-temperature insulation is an insulation with maximum load-bearing capacity that has been specially developed for use in extreme temperatures. It reduces the transfer of thermal energy emanating from hot components and thus protects surrounding components from high temperatures. As a result, a high-temperature insulation not only increases the service life of surrounding components, but also reduces significant risks of various kinds.

In machines and vehicles with combustion engines, electric and hydrogen applications, very high temperatures of over 1,000 °C often prevail. The hot surfaces in the engine compartment give off heat quickly and pose an enormous safety risk to people and machinery, for which conventional thermal insulation systems do not provide sufficient insulation. A high-temperature insulation reduces the heat to an appropriate level and thus not only enables the machine to be started up safely, but also increases efficiency remarkably and helps to comply with strict emission guidelines.

High-temperature insulation is used wherever high temperatures prevail and no proper temperature management poses a risk to people, machines and the economy. In the event of a fire, the consequences are severe. The engine compartment contains both flammable materials and extremely hot surfaces. If both come into contact with each other, a fire can break out. Even if no people are injured, the economic consequences for the company are unpleasant.

That is why more and more companies are opting for high-quality high-temperature insulation, on the one hand to minimise fire risks, but also to benefit from the advantages of modern insulation. We, at the tmax Group, have noticed for many years that the topics of sound, protection against contact as well as the increase in efficiency are of great importance and are explicitly requested by our customers. All these requirements can be implemented with modern insulation solutions and lead to the required results.

|

|

|

|

|

On-Highway |

Agriculture |

High-temperature insulation systems must be robust, durable and efficient. To ensure this, all materials used must be of the highest quality and have very good insulating properties. Optimal density and low heat storage of the insulation material are particularly important, as well as flexible installation and a snug fit of the entire insulation.

A good high-temperature insulation should require the following:

The requirements for high-temperature insulation are as varied and individual as the component to be insulated itself. Depending on the area of application, the following points must be fulfilled:

|

Fulfillment of exhaust emission standards |

Fire protection |

Optimum contact protection |

SOLAS |

|

Protection of surrounding components |

Increase service life |

Efficiency increase |

Soundproofing |

The requirements for high-temperature insulation are diverse. And they can all be realised.

Emission directives are becoming more and more stringent, so efficient exhaust gas aftertreatment is more relevant than ever. This depends on an optimal temperature distribution in the entire exhaust tract. Wherever heat is lost, there is an energy deficit that must be compensated for elsewhere. The right high-temperature insulation prevents energy losses and ensures that optimum temperatures prevail at all important points in the exhaust tract at all times, thus contributing to compliance with emission directives and exhaust gas standards.

The targeted temperature control prevents crystals from forming in the diffuser during urea injection, which makes exhaust gas cleaning less effective. In addition, it also improves light-off behaviour and reduces energy and fuel consumption, making exhaust aftertreatment work earlier and more reliably. This makes CO₂ savings and the achievement of better exhaust gas values possible.

Surface temperatures of up to 850 °C can occur in the engine compartment of machines, vehicles and systems. These high temperatures pose an enormous fire risk, as there are also highly flammable materials in the engine compartment and contact can quickly lead to a fire or explosion. Hydraulic oils and drive fluids ignite at temperatures as low as 250 °C. High-temperature insulation reduces surface temperatures in the engine compartment to a non-hazardous 220 °C to ensure effective fire protection in the event of a leak or deposit of heat-sensitive materials.

For high-temperature applications in the marine sector and on oil platforms, the UN Convention SOLAS (Safety of Life at Sea) stipulates that no exposed component may exceed a surface temperature of more than 220 °C. This and more can be guaranteed by suitable high-temperature insulation.

Engine noise is very loud and, in the long run, represents a high level of stress that is difficult to tolerate and can cause lasting health problems and damage. For this reason, the legal requirements in the area of sound insulation are becoming increasingly strict. In order to comply with them, sound-absorbing measures in the engine compartment are required in addition to thermal insulation.

However, the installation space in vehicles and machines is limited. Thermal and acoustic insulation must be accommodated in the smallest possible space and at the same time fulfil a multitude of requirements. Good high-temperature insulation therefore combines direct thermal insulation with the principle of sound absorption and thus reliably reduces disturbing noise without compromising the thermal and mechanical properties of the insulation or the engine performance.

The right material is crucial for perfect high-temperature insulation. It usually consists of three components: An outer layer, the insulating material and an inner layer, which encase the component to be insulated and reduce hot surface temperatures and radiant heat. The exact structure and the materials used vary according to technical requirements as well as legal regulations and individual customer wishes.

A metallic insulating cladding consists of three components in cassette design: the outer sheet, the insulating material made of glass or silicate fibre and the inner sheet. It encases the component to be insulated and significantly reduces the hot surface temperatures typical of the engine compartment.

Textile insulation

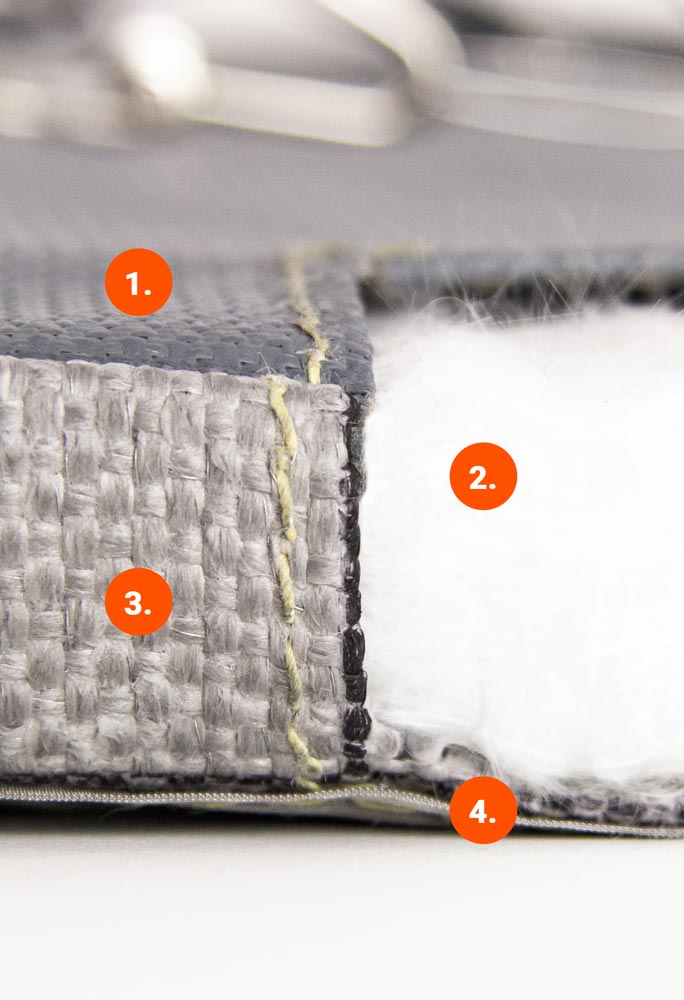

A textile insulation consists of an outer fabric (1), the insulating material (2) made of glass or silicate fibre (3) and an inner fabric (4). The outer fabric protects the insulation from dirt, splash water, oil and other external influences, while the inner fabric is more temperature-resistant and lies directly on the hot component.

In addition, the textile insulation is supported by another vibration-resistant fabric to protect the

insulation system from wear and tear and to

increase its service life.

Foil insulation consists of two to three components. For example, there is integral insulation, which consists of an outer shell made of stainless-steel foil and a moulded fibre part made of insulating fibre (glass or silicate fibre) lying on the component to be insulated. Blankets, on the other hand, have both an outer and an inner shell made of stainless-steel foil, which protect the insulation material inside from damaging influences of all kinds.

Both forms of foil insulation are shaped with the help of embossing and forming tools and ensure optimum high-temperature insulation thanks to their perfect, millimetre-precise fit. The materials and the thicknesses of the insulation insert are developed and combined according to the respective technical requirements.

If required, the insulation fibre mat can also be hydrophobised and is even more effective and durable, even with regular contact with dirt and splash water.

High temperature insulation reduces the passage of heat to a minimum. But how does it work? The basic principle is simple. The lower the density of a body, the worse it works as a heat conductor and the better it works as an insulator.

(High-temperature) insulation materials trap a lot of air in a small space, such as in Styrofoam or between the fibres of flax, rock and glass wool. In this way, the insulating material takes advantage of the physical property of air, because air is a poor conductor of heat.

High-temperature insulation systems from tmax contain a glass fibre or silicate fibre mat that serves as the insulating material. The individual insulation effect can be controlled by varying the thickness of the material.

It is not possible to make general statements about the temperature reductions that can be achieved with high-temperature insulation. This is because the results depend on numerous factors, e.g. the parameters of the component to be insulated and its temperature, the ambient temperature, the insulation material and the material thickness.

The following data refer to a measurement of the insulation effects of tmax high-temperature insulation in different versions, based on the change in surface temperatures of an exhaust pipe. Measurements were taken on an exhaust pipe with a pipe diameter of 100 mm and a wall thickness of t = 2.5 mm at an ambient temperature of 25 °C. Under these basic conditions, a temperature reduction of approx. 50 % upwards can be achieved with high-temperature insulation from a material thickness of 10 mm. With the appropriate insulation thickness, a reduction to a harmless 60 °C can even be achieved.

Basis of calculation:

Pipe diameter: 100 mm

Wallthickness of flue pipe: t = 2,5 mm

Surrounding temperature: 25 °C

| Insulation material | Material thickness | Surface temperature of the insulation at an exhaust gas temperature of 500 °C |

|---|---|---|

| metallic | 10 mm | 155 °C |

| 20 mm | 120 °C | |

| foil | 10 mm | 255 °C |

| 20 mm | 190 °C | |

| textile | 10 mm | 200 °C |

| 20 mm | 145 °C |

| Insulation material | Material thickness | Surface temperature of the insulation at an exhaust gas temperature of 750 °C |

|---|---|---|

| metallic | 10 mm | 250 °C |

| 20 mm | 200 °C | |

| foil | 10 mm | 370 °C |

| 20 mm | 275 °C | |

| textile | 10 mm | 290 °C |

| 20 mm | 220 °C |

| Insulation material | Material thickness | Surface temperature of the insulation at an exhaust gas temperature of 1.000 °C |

|---|---|---|

| metallic | 10 mm | 345 °C |

| 20 mm | 275 °C | |

| foil | 10 mm | 470 °C |

| 20 mm | 360 °C | |

| textile | 10 mm | 380 °C |

| 20 mm | 295 °C |

Disclaimer: The above information is based on our present knowledge of the products specified and is given to the best of our knowledge and belief. The information does not have the meaning of an assurance of properties.

| Material thickness | 10mm | 15mm | 20mm | 25mm | 30mm |

|---|---|---|---|---|---|

| Temperature reduction | 49 – 69% | 58 – 74% | 62– 76% | 74 – 78% | 76 – 80% |

Insulation for particularly high temperatures is an important addition for any type of heat source. If components or machines are properly insulated.

All the advantages of high-temperature insulation at a glance:

Categories

Discover the world of insulation and how tmax, as a market leader, will also solve your requirements.

Fire protection for trains and locomotives is a top priority in rail transport. Find out here how the right high-temperature insulation can reduce...

With proper exhaust tract insulation, all emission targets can be met and the efficiency of the exhaust gas aftertreatment system can be increased.

Minimise fire risks. Optimise fire protection. The correct insulation solution is an important step towards safety. We explain why.